The two types of voltage contactors are AC and DC. AC voltage contactors use an alternating current (AC) to operate, while

DC voltage contactors use direct current. They differ in their resistances, as well as their operating frequencies. AC voltage contractors operate with a higher frequency and have thicker coils, whereas DC contactors do not.

While AC voltage contactors are generally more expensive, DC contactors offer a cost-effective way to switch current in low-voltage DC circuits. They are used in industries such as electric cars, wind power generation, heavy trucks, and solar energy systems. However, they should be carefully chosen to ensure they are suitable for the environment, voltage, and expected current levels.

DC voltage contractors typically use a series of double-winding coils. One is the starting coil, while the other is the holding coil. The main coil is typically unipolar or bipolar and connects to the large current. The auxiliary contact is generally finger contact. The auxiliary contact has a small switching current.

DC voltage contactors have a central functional unit called the arcing chamber. These devices can be mounted horizontally or vertically. Some types feature multiple poles. They can also be angled, so they can be used in different locations. Some of these types are used for alternating current, while others are used for direct current.

DC voltage contactors are usually used when an electrical circuit has a higher frequency than AC. The two types are identical but are made with different types of wiring and materials. The AC type uses soft laminated iron for the electromagnetic core, which minimizes the amount of eddy current loss.

Main Features

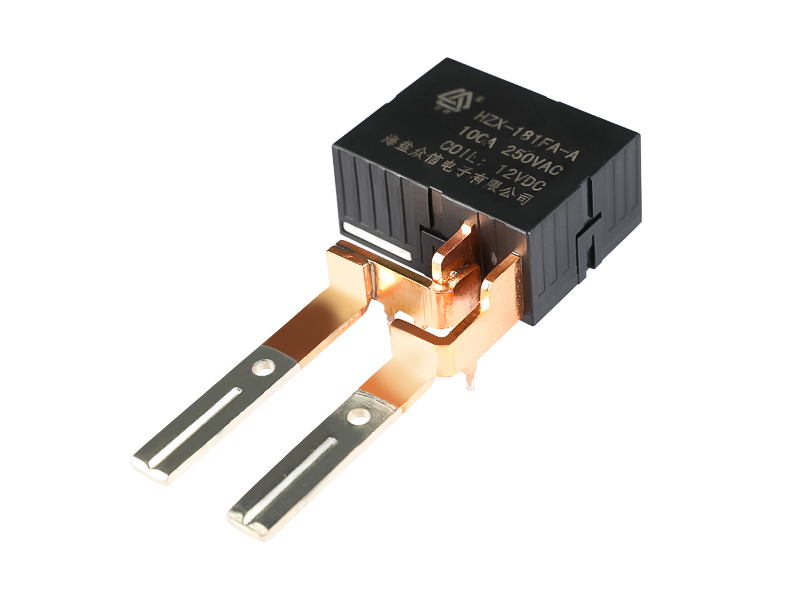

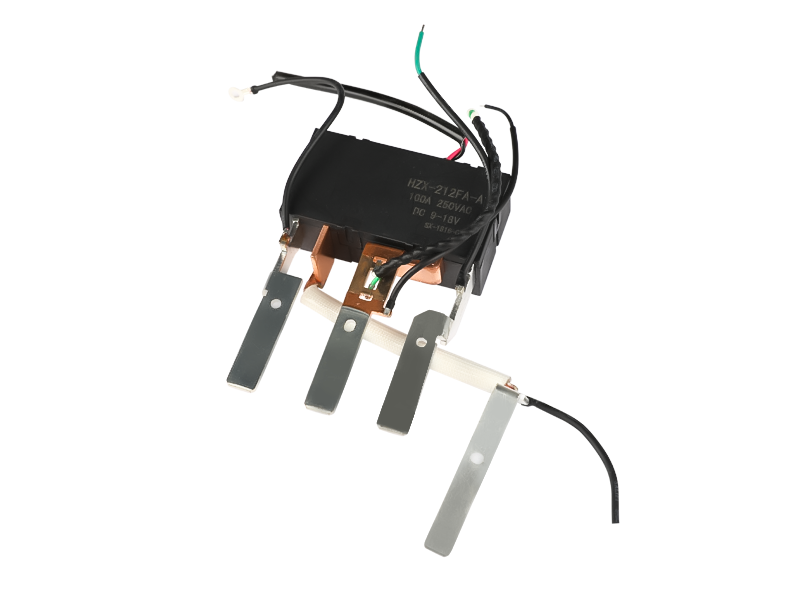

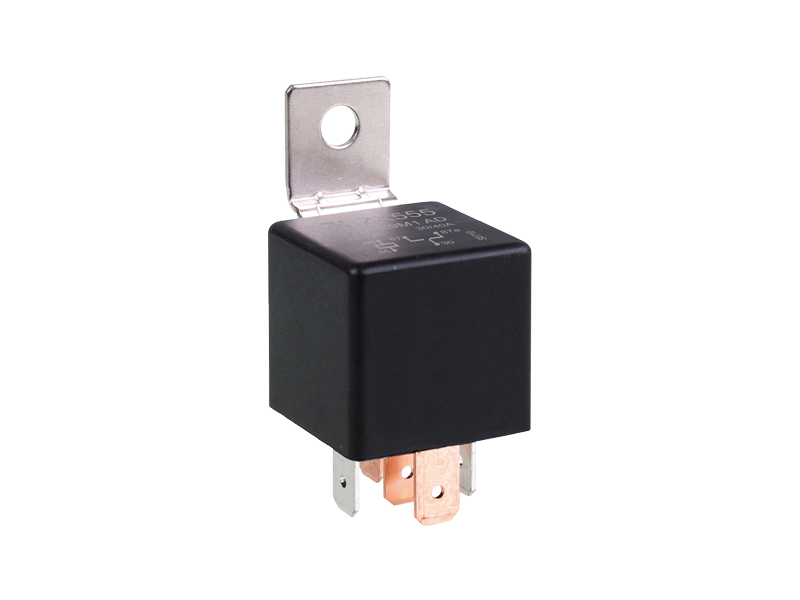

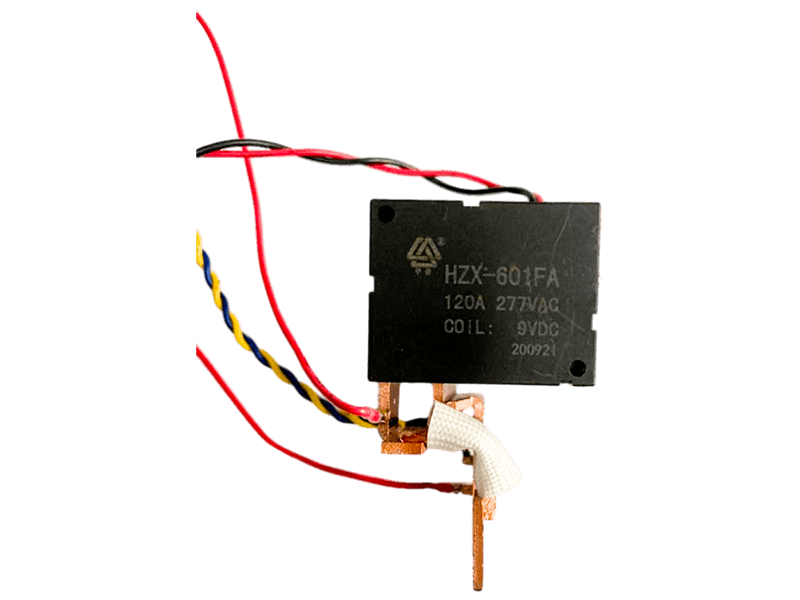

20A continuous current capacity

Direct current relay

Fully standardized quick connect size and layout

Plastic cover for rough environment protection

Typical automotive Applications

Electric vehicle pre-charging