In today’s automotive electrical systems, the demand for reliability has never been higher. Automotive relays, which serve as critical switching components in vehicle electronics, are responsible for controlling circuits that manage lighting, ignition, air conditioning, and safety systems. As vehicles transition toward intelligent, high-load, and high-temperature operating environments, the durability of automotive relays has become the defining factor that determines overall electrical stability and longevity.

Durability is not only a measure of material endurance—it reflects the precision of engineering design, thermal management, and electrical consistency under prolonged stress. Understanding how this single feature shapes the performance of automotive relays reveals much about where the automotive electronics industry is heading.

Unlike ordinary electrical relays, automotive relays operate within fluctuating voltage and temperature ranges, typically from –40°C to +125°C. This variation demands materials and designs capable of maintaining performance across years of continuous operation. A durable relay ensures consistent contact resistance, prevents arcing damage, and maintains switching accuracy even after tens of thousands of cycles.

Durability directly affects system reliability. The failure of a single automotive relay in a lighting or fuel system can trigger cascading electrical malfunctions. This is why automotive relays manufacturers are increasingly focused on improving contact materials, optimizing coil winding designs, and employing protective sealing technologies to extend product lifespan.

Durability in automotive relays is influenced by multiple structural and material considerations. Key aspects include:

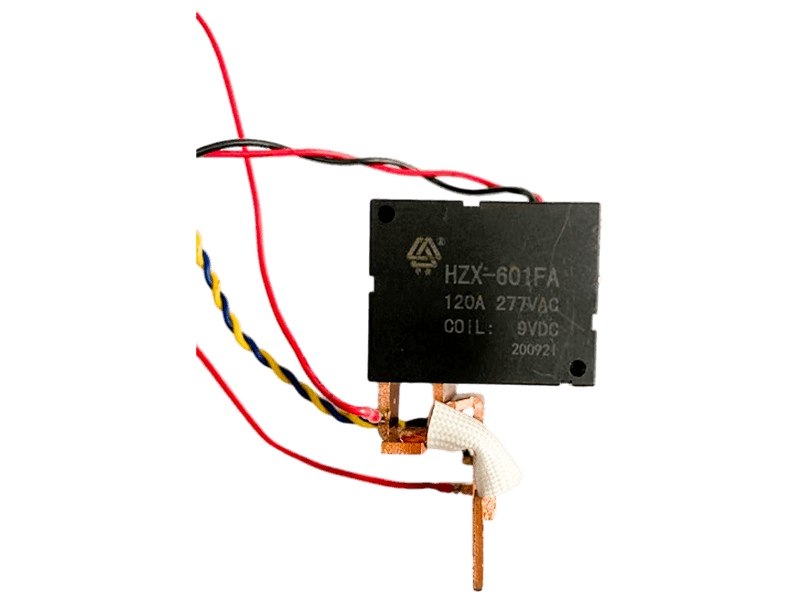

Contact Material Composition – The use of silver alloy, copper-tungsten, or platinum-enhanced surfaces reduces oxidation and minimizes erosion from electrical arcs.

Coil Insulation Quality – High-grade insulation prevents degradation caused by thermal expansion and humidity.

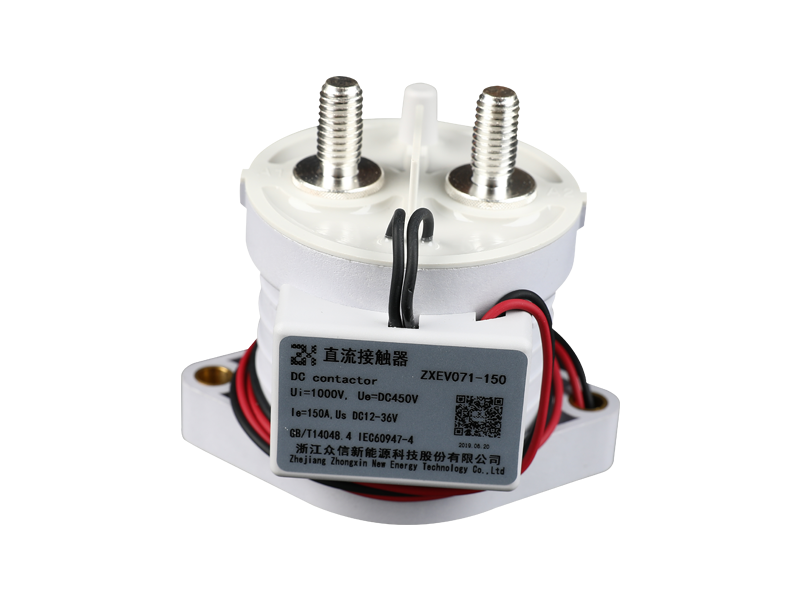

Housing and Sealing – Advanced polymer housings and waterproof sealing enhance resistance to dust, oil, and vibration.

Mechanical Structure – Precision spring design ensures consistent contact force over long cycles.

Thermal Dissipation Design – Efficient heat conduction materials maintain stable temperature during prolonged high-current operation.

| Parameter | Mechanical Relays (Standard) | Sealed Automotive Relays | Heavy-Duty Power Relays |

|---|---|---|---|

| Contact Endurance (cycles) | 50,000–100,000 | 100,000–300,000 | 300,000+ |

| Operating Temperature Range | -25°C to +85°C | -40°C to +125°C | -40°C to +150°C |

| Resistance to Moisture/Dust | Moderate | High (IP67–IP69K) | High (IP69K+) |

| Typical Current Capacity | 20–30A | 40A | 70–100A |

| Application Area | General vehicle systems | Engine and lighting units | Powertrain, EV modules |

To ensure reliability, automotive relays manufacturers subject their products to a range of standardized endurance tests. These include:

Thermal Shock Tests: Relays are cycled between temperatures to assess structural integrity.

Vibration and Shock Resistance: Evaluates performance stability in dynamic environments such as engine compartments.

Contact Wear Tests: Measures the lifespan of electrical contacts under repeated load switching.

Humidity and Corrosion Resistance: Determines the effectiveness of sealing and material resistance.

By performing these tests, manufacturers can verify compliance with international automotive standards while ensuring consistent performance under real-world driving conditions.

The pursuit of greater durability has accelerated innovation in relay materials and design. Emerging trends include:

Solid-State Relay Integration – While still evolving, solid-state designs offer increased lifespan due to the absence of mechanical wear points.

Nano-Coated Contacts – Surface coatings enhance conductivity while reducing corrosion risk.

Thermally Conductive Housing Materials – Help dissipate heat faster, extending the operational life of internal components.

Miniaturized High-Endurance Designs – Compact, low-resistance relays are being optimized for modern EV and hybrid systems.

For engineers and procurement teams, selecting automotive relays with proven durability is no longer optional. It is a performance benchmark. The expected lifetime of vehicle electronics now often exceeds ten years, and every component must match that standard. Durability ensures reduced replacement cycles, improved vehicle reliability, and consistent functionality under conditions.

Moreover, the trend toward electrification increases the demand for relays that can manage higher current loads without degradation. Durable automotive relays thus serve as key enablers in the transition to electric and hybrid powertrains.

As durability becomes the decisive factor influencing product quality and brand reputation, automotive relays manufacturers are recalibrating their production lines toward higher endurance standards. Investments in automated testing systems, precision tooling, and advanced material synthesis are driving the evolution of this sector.

The demand for heavy-duty automotive relays, waterproof automotive relays, and high-current automotive relays is expanding across both traditional and electric vehicle markets. Manufacturers capable of demonstrating durability metrics are likely to dominate future supply chains, as vehicle OEMs continue to prioritize long-term reliability and reduced maintenance costs.

In the era of intelligent and electrified vehicles, automotive relays are no longer viewed as simple mechanical switches. They are precision-engineered components central to safety, efficiency, and control. Durability—manifested through advanced materials, sealing technologies, and thermal design—defines the next generation of relay performance standards.