Typical applications of

high voltage direct current contactors are in electric vehicles, motor control, and circuit protection. They also provide galvanic isolation of the grid and load. However, using them in conditions beyond the switching capacity of the contactor can result in damage to the surrounding parts. Hence, it is important to choose a contractor that has the necessary life and functional qualities. It is also important to design the electrical circuit of a contactor so that the power supply can be cut off in one second.

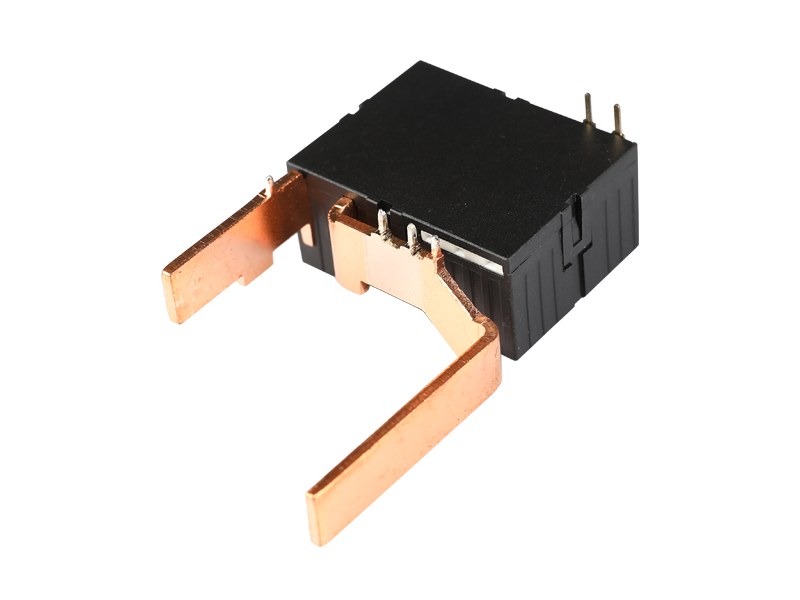

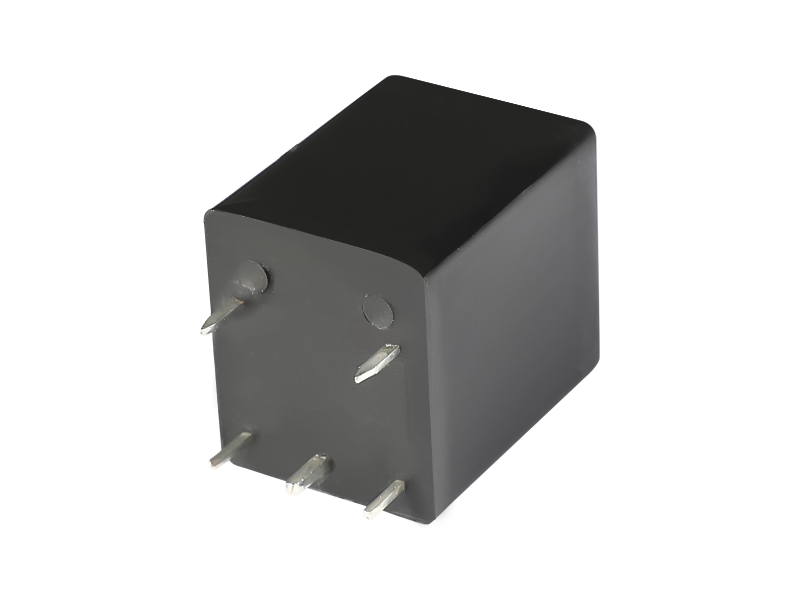

Contactors consist of a coil and two main contacts. When the contactor is operated, the coil will generate a magnetic field that attracts a moving core to the open contacts. At the same time, the voltage across the contacts will build up until a high-voltage direct current is generated. This voltage will then be reduced to zero.

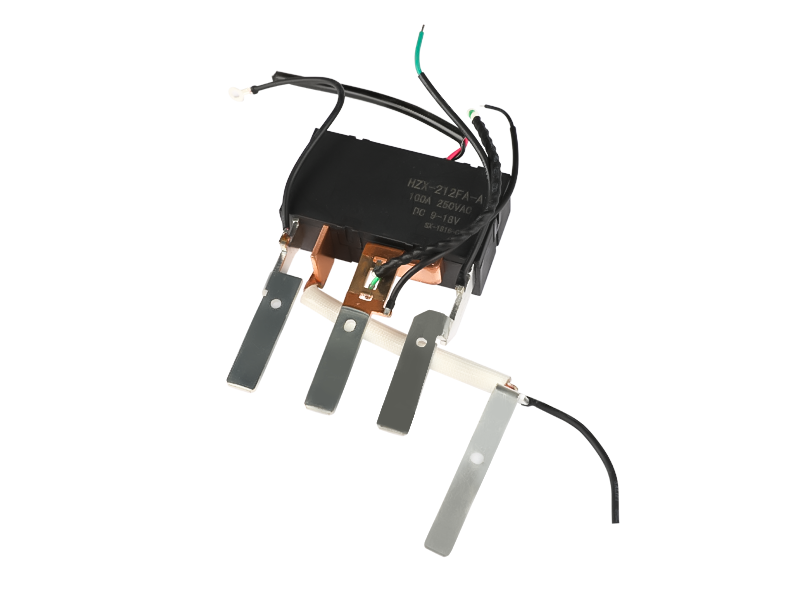

Contactors are also available in a simplified version without diodes VD2, VD7, and thyristor VS2. These are used in cases where there is a single direction of current and no voltage drop. They are also not suited for reverse patterns of switching. However, their basic electronic pattern can be calculated accurately for circuits involving commuting currents up to 1000V.

A smart contractor has special controls and diagnostic features. These may include a mechanical latching function performed by a hardened steel plate pinned to the plunger. It also has pulse-width modulation with voltage feedback. These features are used to minimize power consumption and extend the life of the contactor. However, the feedback accuracy is low. In addition, it requires pre-calibration work.

Contactors are available with either economized or non-economized coils. The economized coil has a built-in internal economizer. This means that the contractor only needs to power the coil terminals and not external circuits that generate the desired current waveform. However, it does not feature an internal circuit for generating the required voltage. Therefore, it is important to provide the coil with the necessary voltage. If it does not economize, it is necessary to provide external circuits to generate the desired voltage.

1. Small and lightweight:Internally adopt reliable sealing technology and filled with nitrogen which arc colling ability is high. It can cut off high voltage DC in a short time.

2. High contact reliability:Due to the contact sealed in the nitrogen, therefore it will be not oxidized, also achieving the contact of the dustproof and waterproof.

3. Safety and reliable:Use the professional explosion-proof structure design,to achieve a high degree of security,adopt magnetic quenching helps to cut-off the DC load quickly.