In modern industrial electrical control systems, contactors are essential key components, and high voltage direct current contactors are one of the advanced applications. High voltage direct current contactors are mainly used in high-voltage DC circuits to control, switch and protect current. With the continuous development of power systems and the expansion of the application of high-voltage DC technology, the role of high voltage direct current contactors is becoming more and more important.

Definition and basic working principle of high voltage direct current contactor

High voltage direct current contactor is an electrical device used to control the on and off of high-voltage DC current. It uses electromagnetic principles to open and close the contact points under the action of current, thereby achieving control of the circuit. The main functions of the contactor include:

Current switch: High voltage DC contactors can quickly disconnect or close current in the circuit to ensure stable transmission and control of current.

Overload protection: When the current in the circuit exceeds the specified value, the contactor will disconnect the circuit to avoid equipment damage due to overload.

Short circuit protection: The contactor can also provide short circuit protection to prevent the circuit from being dangerous due to short circuit.

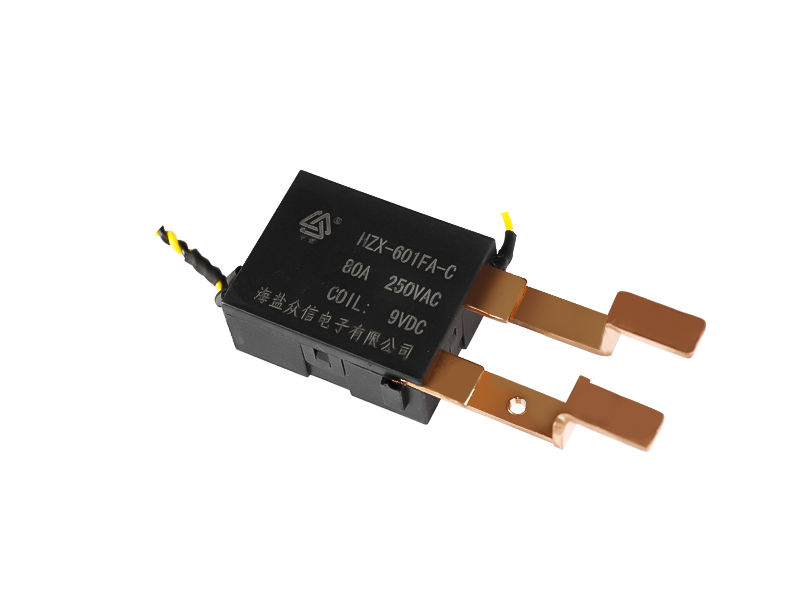

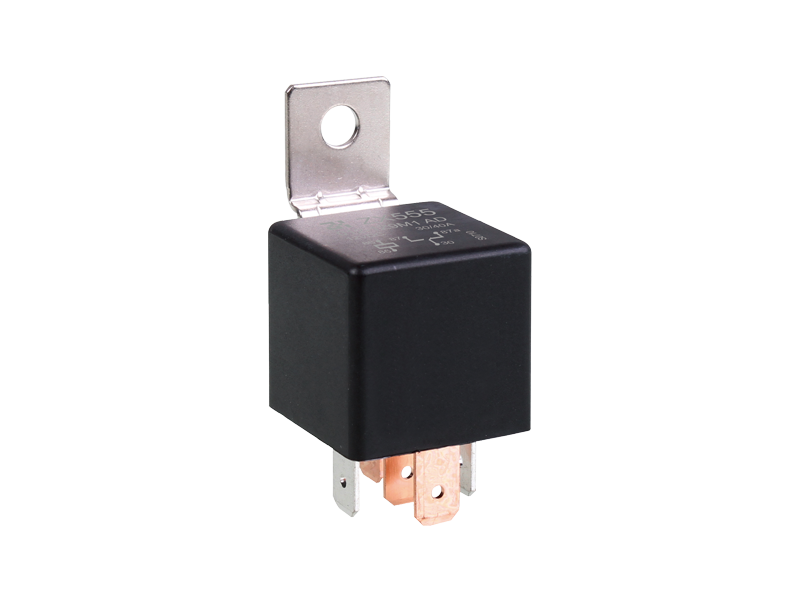

High voltage direct current contactor usually consists of electromagnetic coil, contacts, springs and other auxiliary components. When the electromagnetic coil is energized, a magnetic field is generated to push the contacts to close or open, thereby controlling the on and off of the circuit.

Application fields of high voltage direct current contactor

High voltage DC contactors are widely used in many fields, especially in the following aspects:

High voltage DC power supply system: In large power systems, especially in places such as substations and transmission lines, the stable transmission of power is crucial. High voltage direct current contactor can be used to control the connection and disconnection of DC power supply to ensure the safe operation of the power system.

Electric vehicles: With the development of electric vehicle technology, high voltage direct current contactor is widely used in the battery management system of electric vehicles, responsible for the current control and battery protection of battery packs.

Power electronic equipment: High voltage direct current contactor also has important applications in power electronic equipment such as inverters and power converters, which are used to control the input and output of DC power supply.

Renewable energy field: In the power generation system of renewable energy such as solar energy and wind energy, high voltage direct current contactor helps regulate the transmission of electric energy, especially when connected to the power grid.

Technical requirements of high voltage direct current contactor

Since high voltage DC contactors are mainly used in high voltage environments, some technical requirements need to be paid special attention to during their design and manufacturing.

High voltage resistance: High voltage DC contactors need to have very strong voltage resistance to withstand DC voltages up to several thousand volts.

Quick response capability: Since the high voltage DC current switches frequently and the current changes rapidly, the contactor must have the characteristics of fast response to ensure the rapid disconnection or closing of the circuit.

Low contact resistance: In order to reduce energy loss and improve efficiency, the contacts of high voltage DC contactors must have extremely low contact resistance.

Stability and reliability: High voltage DC contactors must be able to work stably for a long time in harsh environments to ensure the safety of the system.

Selection and maintenance of high voltage direct current contactor

When selecting, users need to make reasonable choices based on factors such as the voltage level, working environment, and load characteristics of the actual application. Good maintenance is also the key to ensure the long-term stable operation of high voltage DC contactors.

Key points of selection: When selecting a high voltage DC contactor, parameters such as the rated voltage, rated current, and control capability of the contactor should be considered to meet actual needs.

Regular inspection: The contacts of high-voltage DC contactors are susceptible to wear after long-term operation, so it is necessary to regularly check the wear of the contacts and replace them in time.

Cleaning and lubrication: Regularly clean the dust and dirt inside the contactor to keep the contact points clean to improve contact performance and extend service life.

As a core component in the power control system, high voltage direct current contactor is increasingly used in modern electrical engineering. With the continuous advancement of technology, future high-voltage DC contactors will be more intelligent, efficient and reliable, providing better solutions for multiple fields such as industry, transportation, and electricity.