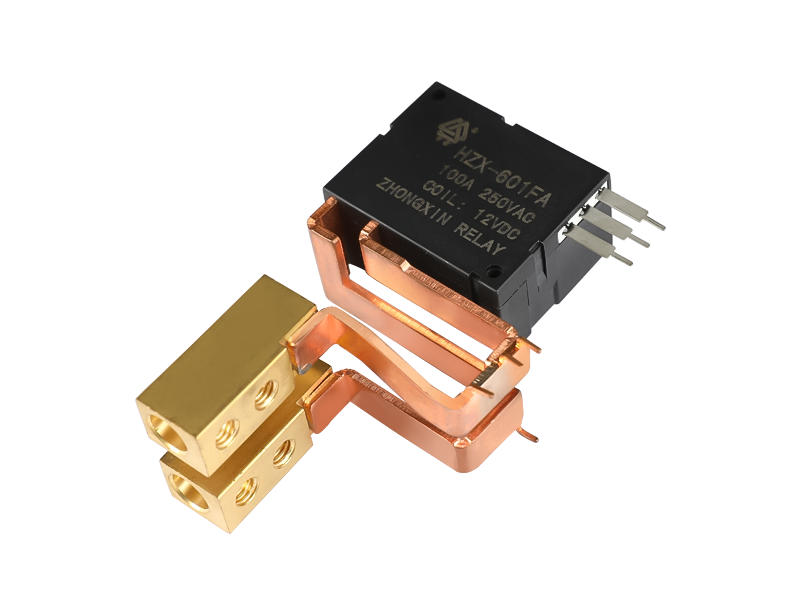

The evolution of high voltage power systems has accelerated the demand for robust switching solutions capable of handling conditions. Among these, the high voltage direct current (HVDC) contactor has emerged as a cornerstone technology. Its unique ability to manage DC power in high-voltage environments makes it essential for renewable energy, electric vehicle infrastructure, and industrial power distribution.

Unlike AC systems, DC circuits do not experience natural zero-crossing of current, which makes breaking DC circuits inherently more challenging. A high voltage direct current contactor must be designed to withstand prolonged arcing during switching events. Reliability in this context refers not only to the ability to make and break circuits without failure but also to maintaining consistent performance across operational cycles.

Contact Material and Coatings:

The choice of contact material significantly affects the wear rate and electrical resistance of HVDC contactors. Materials such as silver alloys and specially coated metals enhance conductivity while reducing erosion from electrical arcs.

Mechanical Design:

A compact, robust mechanical structure ensures that the contactor can endure repetitive operations without deformation. This includes spring mechanisms, guide systems, and housing integrity.

Arc Suppression Mechanisms:

Advanced arc suppression methods, including magnetic blowouts or vacuum interrupters, allow the contactor to safely interrupt high-voltage DC currents without damage.

High voltage DC contactors are extensively used in sectors where failure is not an option. Key applications include:

| Application Area | Role of HVDC Contactor | Benefits of High Reliability |

|---|---|---|

| Renewable Energy (Solar & Wind) | Switch DC power from panels or turbines to inverters | Prevents downtime and energy loss |

| Electric Vehicles and Charging Stations | Manages high-current DC battery circuits | Ensures safe battery operation and long lifespan |

| Industrial Power Distribution | Provides DC switching in heavy machinery | Reduces maintenance and operational risk |

| Battery Energy Storage Systems | Connects and disconnects large DC battery banks | Maintains system stability and efficiency |

In all these applications, long-term reliability translates into fewer maintenance interventions, improved safety, and uninterrupted power delivery.

A high voltage direct current contactor must combine electrical performance with mechanical endurance. Advanced engineering approaches focus on extending contact life and minimizing downtime.

| Feature | Description | Benefit |

|---|---|---|

| Silver-plated contacts | Reduces wear from arcing and maintains low contact resistance | Longer operational lifespan |

| Magnetic arc blowout | Directs and extinguishes electrical arcs | Prevents contact degradation |

| High-strength spring system | Ensures consistent contact pressure | Reduces mechanical failure |

| Insulated housing materials | Provides thermal and electrical isolation | Enhances safety and performance stability |

| Multi-stage switching mechanism | Allows staged engagement to reduce arcing | Improves reliability under load |

These design elements collectively improve the overall durability of HVDC contactors and enhance operational efficiency in demanding environments.

The integration of high voltage direct current contactors requires careful consideration of system parameters. Power engineers must assess voltage ratings, current capacity, switching frequency, and environmental conditions.

Key integration considerations include:

| Specification | Description |

|---|---|

| Maximum DC Voltage | Up to 1500V or higher depending on system requirements |

| Rated Continuous Current | Ranges from 50A to 2000A |

| Mechanical Endurance | Over 1 million operational cycles |

| Operating Temperature Range | -40°C to +85°C |

| Switching Time | <50 milliseconds |

These parameters highlight the critical role of engineering in optimizing both performance and reliability for HVDC contactors.

With increasing deployment of renewable energy and electrified transportation, high voltage direct current contactors will play a pivotal role in energy transition. Reliability remains a primary differentiator, influencing operational efficiency, safety, and long-term system costs.

Emerging trends focus on:

In essence, a high-reliability HVDC contactor is not just a switching device—it is a critical enabler of safe, efficient, and sustainable power systems.