Electromagnetic relays are crucial components in various electrical and electronic systems, offering high reliability and versatility in controlling circuits. These devices operate by using an electromagnet to open or close contacts, allowing the relay to control the flow of current. Understanding how to maximize efficiency in electromagnetic relay applications is essential for improving the performance, lifespan, and energy consumption of electrical systems.

An electromagnetic relay is a switching device that opens or closes a circuit when an electrical signal is applied to the relay coil. These relays are used to control high-voltage or high-current devices with low-power signals, making them indispensable in applications ranging from industrial automation to household appliances.

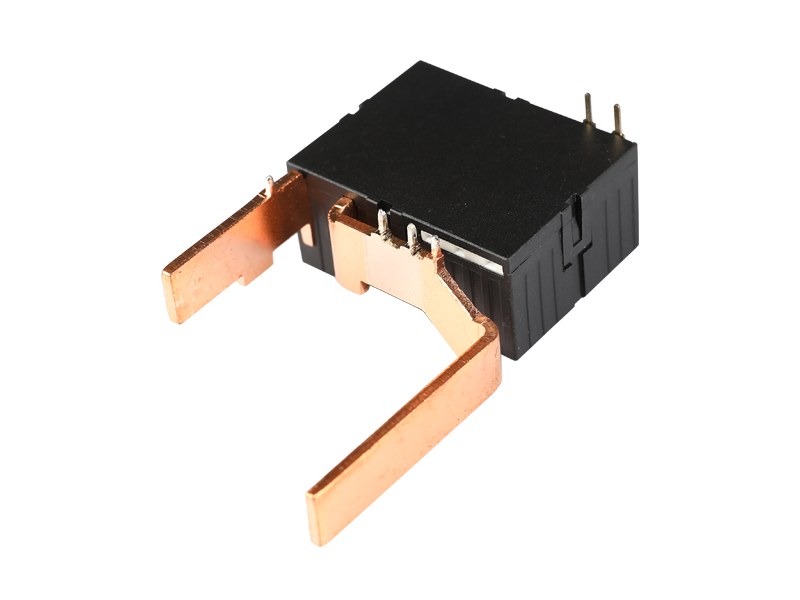

Key Components:

The efficiency of a relay is determined by the speed of its operation, the quality of the contacts, and the strength of the magnetic field generated by the coil.

Several factors influence the overall efficiency of electromagnetic relays in their applications. These include design considerations, electrical characteristics, and environmental conditions.

One of the primary factors in relay efficiency is managing the coil resistance. A lower coil resistance reduces power consumption, which is especially important in battery-powered systems. However, reducing resistance too much can impact the strength of the magnetic field generated, which results in slower or weaker switching.

Tip: Select a coil resistance value that balances power consumption with reliable performance.

The choice of contact material plays a significant role in the longevity and reliability of the relay. Contacts made from materials like silver or gold alloys offer high durability and low contact resistance, which reduces power loss and improves efficiency.

Tip: Choose high-quality contact materials to minimize wear and tear, improving relay lifespan.

The switching speed of a relay directly affects the overall system efficiency. Faster switching relays reduce the delay between control signals and the actual switching event, which is crucial for high-speed automation and communication systems.

Tip: Choose relays with high-speed operation if your application demands quick response times.

Electromagnetic relays are often subjected to varying environmental conditions, including temperature fluctuations, humidity, and exposure to dust or moisture. Extreme conditions can cause relay failure or reduced efficiency.

Tip: Use relays that are rated for specific environmental conditions to ensure long-term reliability.

Maximizing the efficiency of electromagnetic relays involves optimizing their design, installation, and maintenance.

Selecting the right relay for your application is crucial for efficiency. A relay that is too large or too small for the load it controls can result in wasted energy, overheating, or unreliable operation.

Tip: Ensure that the relay’s voltage and current ratings match the requirements of your system.

Over time, mechanical wear on the armature and contacts can reduce relay efficiency. To minimize wear, use relays with high-quality materials and ensure that the relay is not exposed to excessive mechanical stress.

Tip: Regularly inspect relays for signs of wear and replace them as needed to maintain performance.

Maintaining electromagnetic relays is key to ensuring their efficiency over time. Regular inspection, cleaning, and testing can help detect potential issues before they cause system failure.

Tip: Implement a scheduled maintenance program to inspect and test relays periodically.

Even with the setup, problems can arise that impact relay efficiency. Identifying and troubleshooting these issues promptly is essential to avoid costly downtime.

| Issue | Cause | Solution |

|---|---|---|

| Slow switching | High coil resistance or wear | Check coil resistance and replace contacts if necessary. |

| Relay not activating | Low control voltage | Verify control circuit voltage and ensure proper wiring. |

| Overheating | Excessive load or poor ventilation | Reduce load and improve cooling. |

| Relay chatter | Insufficient coil voltage or mechanical wear | Inspect coil voltage and check for wear on the armature. |

In automation systems, electromagnetic relays are used to control motors, sensors, and other devices. Ensuring fast and reliable switching is crucial for system efficiency.

Tip: Use relays with high-speed switching capabilities and minimal contact resistance to improve overall automation performance.

In power distribution systems, relays are used to protect circuits and ensure proper load distribution. Maximizing relay efficiency in these systems helps to minimize energy loss and maintain system stability.

Tip: Choose relays with appropriate voltage and current ratings to match the power distribution requirements.

Maximizing efficiency in electromagnetic relay applications requires careful consideration of several factors, including coil resistance, contact material, switching speed, and environmental conditions. By selecting the right relay, maintaining it properly, and optimizing its design and installation, you can ensure that your electromagnetic relays operate at peak efficiency.

Q1: How do I choose the right electromagnetic relay for my application?

A1: Select a relay based on the voltage and current ratings required by your application. Consider factors such as switching speed and environmental conditions.

Q2: What maintenance practices can improve relay efficiency?

A2: Regularly inspect, clean, and test relays to ensure they are functioning properly. Replace worn components as needed.

Q3: Can I reduce power consumption with an electromagnetic relay?

A3: Yes, by selecting a relay with coil resistance and efficient contact materials, you can reduce power consumption.

Q4: What are the environmental factors that affect relay efficiency?

A4: Temperature, humidity, and exposure to dust or moisture can impact relay performance. Choose relays rated for the specific conditions of your application.

Q5: How can I troubleshoot relay efficiency issues?

A5: Check for high coil resistance, mechanical wear, or insufficient voltage. Regular inspections can help identify potential issues early.