As rail transit systems continue to become increasingly intelligent, the upgrade of core electrical components has become a key driver of system performance. Against this backdrop, technological breakthroughs in magnetic latching relay for rail meters are bringing structural optimization and functional gains to flexible connection solutions for rail instruments, driving rail transit equipment towards greater efficiency, stability, and intelligence.

Structural Reshaping: The Emergence of a New Paradigm for Flexible Connections

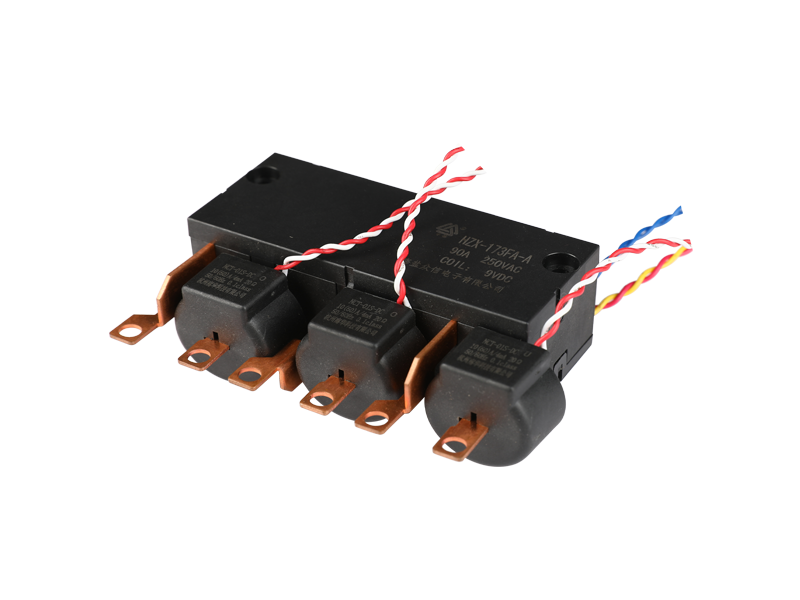

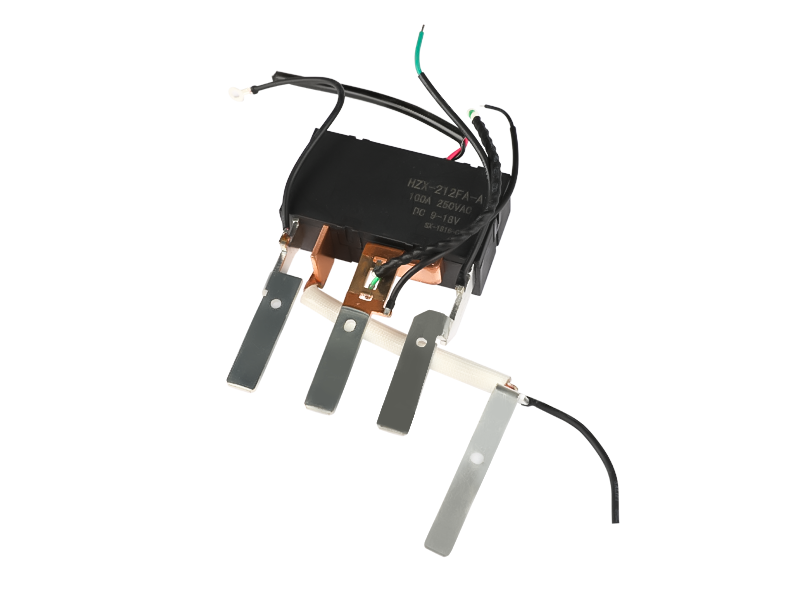

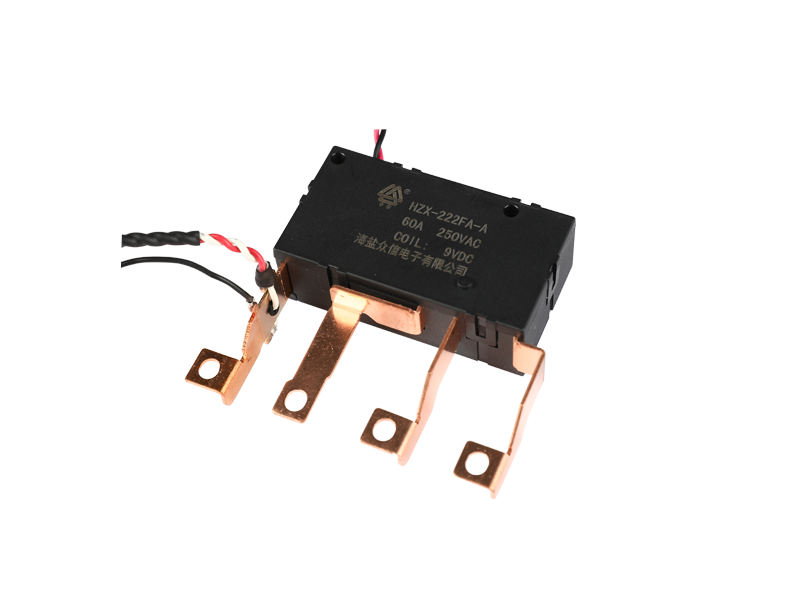

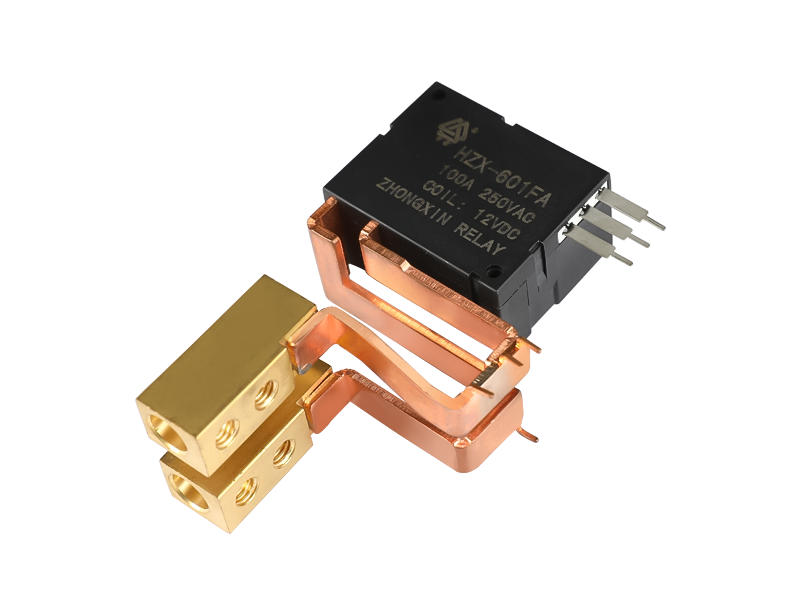

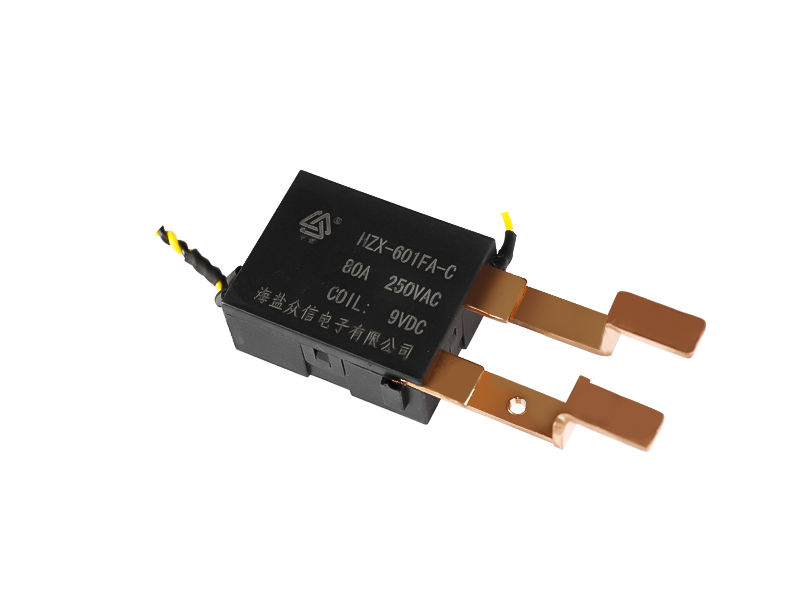

In traditional rail instrument systems, current on/off control primarily relies on bulky, energy-intensive mechanical relays, which not only imposes space constraints but also limits instrument integration flexibility. The next-generation magnetic latching relay flexible connection for rail meters, with its lightweight design and low power consumption, provides the physical foundation for modular and flexible deployment of rail instruments. A notable feature of magnetic latching relays is their bistable structure—the contact position remains unchanged when de-energized, significantly reducing system maintenance power consumption. This feature ensures stable operation and electrical system safety despite complex signal switching and high-frequency control requirements. At the connection level, this relay supports flexible bridging between high-current loads and precision instruments, effectively avoiding contact risks and interference issues associated with rigid layouts.

Core Technology: Co-evolution of Electromagnetic Latching and Mechanical Performance

The widespread attention paid to magnetic latching relays in rail transit applications stems from the maturity and high compatibility of their core technologies. The magnetic latching relay used in rail transit instruments adopts permanent magnets and bipolar magnetic circuits to achieve discontinuous control of electromagnetic state. Energy is consumed only during the transient state transition, eliminating the need for a holding current during the off-cycle. This approach not only alleviates energy consumption pressures on rail power supply systems but also significantly improves the relay's reliability in high-temperature, high-humidity, and high-vibration environments. Mechanically, magnetic latching relays combine a high-strength contact system with anti-vibration springs, providing enhanced shock resistance in rail operating environments and ensuring contact stability and low-temperature rise characteristics despite frequent and prolonged actuation. Furthermore, their housings are typically made of flame-retardant polymers, offering insulation properties and environmental adaptability, providing a solid foundation for the long-term operation of rail instrumentation systems.

System Adaptation: From Local Upgrades to Overall Performance Transformation

The operational characteristics of rail instrumentation require electrical connection systems to possess comprehensive performance features such as fast response, low latency, and high stability. Within this framework, the integrated implementation of latching relays is no longer simply a replacement of a single component, but rather a systematic upgrade towards a flexible connection architecture. By employing latching relays in critical signal paths, rail instrumentation can maintain state and execute tasks without relying on a continuous power supply, simplifying the design of peripheral control circuits and improving overall system redundancy and fault resilience. Furthermore, these relays can be flexibly integrated with a variety of communication modules and protection units, providing both local response and remote monitoring, enhancing data visibility and controllability for rail instrumentation. In practice, latching relays demonstrate interface compatibility and environmental adaptability in a variety of applications, including onboard monitoring, wayside signaling, and feeder protection, providing a unified and efficient solution for flexible rail instrumentation connections.

Deepening Applications: Driving Comprehensive Upgrades of Intelligent Rail Transit Systems

As urban rail transit moves towards intelligent and digital development, the role of rail instrumentation is gradually evolving from simple monitoring to intelligent decision-making. This transformation places higher demands on the intelligent scheduling and energy-efficient control of the underlying electrical system, and magnetic latching relays are the key bridge to achieving this goal. In future application scenarios, magnetic latching relay for rail meter can be further integrated with intelligent algorithms and state-aware modules to achieve dynamic linkage between relay status and system tasks, driving the evolution of rail metering from "connected execution" to "data-driven." At the same time, their programmable control features provide rail systems with stronger logical adaptability, improving the overall architecture's response efficiency and resilience to emergencies. Especially in rail transit networks with multiple nodes and heterogeneous systems, magnetic latching relays, with their high reliability, low power consumption, and compact structure, are expected to become a core component of standardized, modular interface solutions in next-generation rail control systems, further promoting the integrated and intelligent development of rail transit equipment.