In modern industrial and electronic applications, controlling electrical circuits efficiently and reliably is essential. Relays play a critical role in this process, acting as switches that allow circuits to be controlled remotely or automatically. Among the commonly used types are electromagnetic relays and solid-state relays. Choosing the right relay can significantly affect the performance, longevity, and safety of your system.

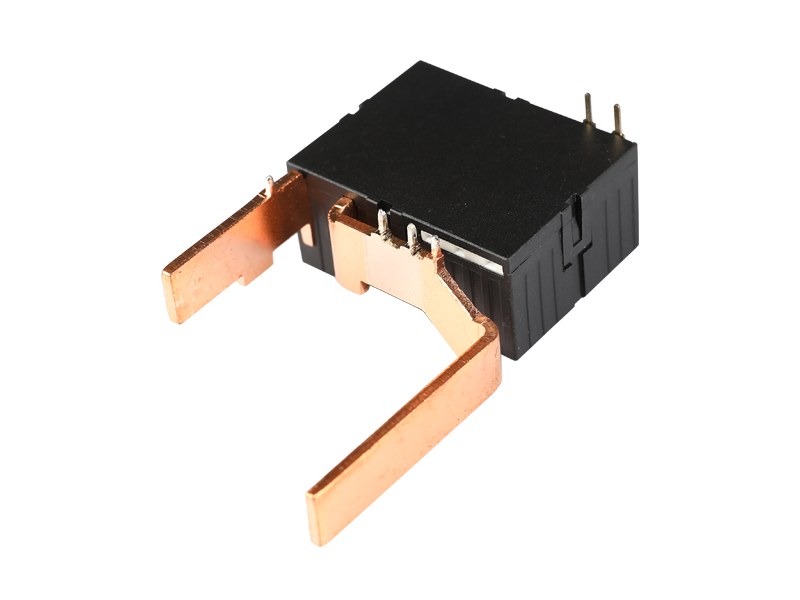

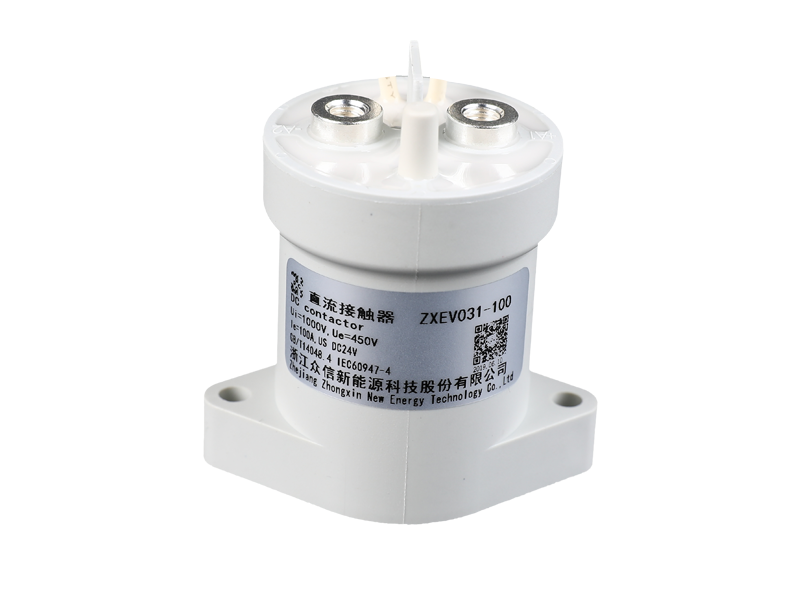

An electromagnetic relay is a type of electrically operated switch that uses an electromagnet to mechanically operate one or more sets of contacts. When a current flows through the coil of the relay, it generates a magnetic field, which attracts or repels a movable armature. This movement opens or closes the contacts, allowing electrical current to flow through the load circuit.

Electromagnetic relays are widely recognized for their simplicity, robustness, and versatility. They can handle a wide range of currents and voltages, making them suitable for applications from household appliances to industrial machinery.

| Feature | Description |

|---|---|

| Switching Mechanism | Mechanical, using a movable armature and contacts |

| Load Capacity | Can handle high currents and voltages |

| Response Time | Moderate (typically milliseconds) |

| Durability | Mechanical wear may limit lifespan with frequent switching |

| Isolation | Provides electrical isolation between control and load circuits |

Electromagnetic relays are highly effective in scenarios requiring physical separation between the control circuit and the load. This makes them ideal for high-power applications where operator safety is crucial.

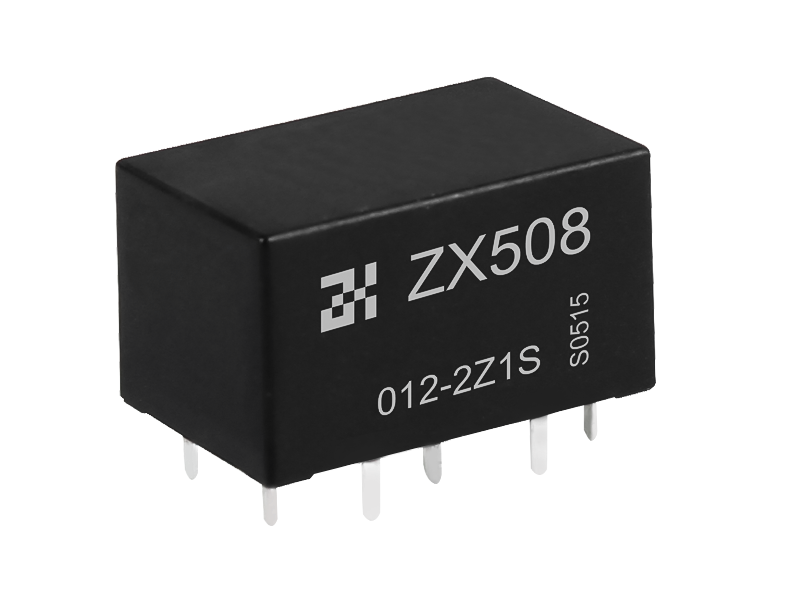

A solid-state relay (SSR) is an electronic switching device that performs the same function as an electromagnetic relay but without moving parts. Instead of using a mechanical armature, SSRs use semiconductor devices such as thyristors, triacs, or transistors to switch electrical loads.

Solid-state relays offer silent operation, extremely fast switching, and high reliability, especially in applications requiring frequent on/off cycles. They also have resistance to mechanical shock and vibration, making them suitable for harsh industrial environments.

| Feature | Description |

|---|---|

| Switching Mechanism | Semiconductor-based, no moving parts |

| Load Capacity | Suitable for medium to high currents, but limited by heat dissipation |

| Response Time | Very fast (microseconds to milliseconds) |

| Durability | Long lifespan due to absence of mechanical wear |

| Isolation | Electrical isolation typically achieved with opto-isolators |

SSRs are often preferred in systems requiring precise timing, high-speed switching, or reduced maintenance due to their long operational life.

Understanding the differences between electromagnetic relays and solid-state relays is crucial to selecting the right device for your application. The following table provides a side-by-side comparison of their main characteristics:

| Aspect | Electromagnetic Relay | Solid-State Relay |

|---|---|---|

| Switching Method | Mechanical contacts | Semiconductor devices |

| Response Time | Milliseconds | Microseconds to milliseconds |

| Lifespan | Limited by mechanical wear | Very long, limited by heat |

| Noise | Audible clicking sound | Silent operation |

| Load Handling | Can handle high surge currents | Sensitive to inrush currents |

| Maintenance | Requires periodic checks | Minimal maintenance required |

| Cost | Generally lower | Higher initial cost |

| Efficiency | Minimal power consumption in coil, but mechanical losses | Higher efficiency, minimal heat if properly cooled |

The choice between the two depends largely on the specific requirements of the application.

Electromagnetic relays are widely used in industries where electrical isolation, high current handling, and robustness are critical. Common applications include:

Industrial Automation: Controlling motors, pumps, and industrial machinery.

Power Systems: Switching high-voltage circuits, overload protection.

Home Appliances: Used in refrigerators, air conditioners, and washing machines.

Safety Systems: Emergency shutdown circuits due to reliable mechanical isolation.

Despite the rise of solid-state relays, electromagnetic relays remain relevant due to their simplicity and ability to handle high transient currents without damage.

Solid-state relays are preferred in applications where fast switching, long operational life, and silent operation are priorities. Typical applications include:

Precision Electronics: Switching circuits in computers, sensors, and measurement devices.

Lighting Systems: Dimming and controlling high-frequency lighting loads.

Industrial Heating: Controlling resistive heating elements with high-frequency switching.

Automation Systems: Conveyor belts, automated packaging, and robotics.

SSRs are especially beneficial in high-speed applications where mechanical wear of electromagnetic relays would be a limiting factor.

When deciding between an electromagnetic relay and a solid-state relay, consider the following factors:

Load Type and Current: High inrush currents favor electromagnetic relays.

Switching Frequency: High-frequency switching favors solid-state relays.

Lifespan Requirements: SSRs generally offer longer operational life.

Environmental Conditions: Electromagnetic relays may be more tolerant to high temperatures, whereas SSRs require proper heat management.

Noise Considerations: SSRs operate silently, while electromagnetic relays generate clicking sounds.

Cost and Maintenance: Electromagnetic relays have lower upfront costs but may require more maintenance over time.

| Parameter | Electromagnetic Relay | Solid-State Relay | Recommended Use Case |

|---|---|---|---|

| High Current Loads | Excellent | Moderate | Heavy industrial machinery |

| High Switching Frequency | Moderate | Excellent | Automated conveyor systems |

| Noise-Sensitive Environment | Moderate | Excellent | Laboratories, hospitals |

| Maintenance Requirement | Higher | Minimal | Long-term automated operations |

| Budget Constraint | Lower | Higher | Small-scale applications |

Relays are typically integrated into control panels, PLC systems, and automation devices. Selecting the right relay ensures safety, reliability, and operational efficiency. While electromagnetic relays are simple to wire and test, SSRs require attention to heat sinks, proper isolation, and thermal management.

Electromagnetic Relays: Ensure mechanical mounting is secure and that there is sufficient clearance for moving parts. Coil voltage should match control circuitry.

Solid-State Relays: Pay attention to heat dissipation and follow manufacturer guidelines for load connections. Proper isolation from high voltages is critical.

Regardless of the relay type, consider these performance indicators during system integration:

Choosing between an electromagnetic relay and a solid-state relay depends on the specific requirements of your application. Electromagnetic relays offer robustness, high current handling, and isolation, while solid-state relays provide fast switching, silent operation, and minimal maintenance. By understanding the operational characteristics, applications, and limitations of each type, you can make a well-informed decision that maximizes performance, reliability, and longevity in your electrical or industrial systems.