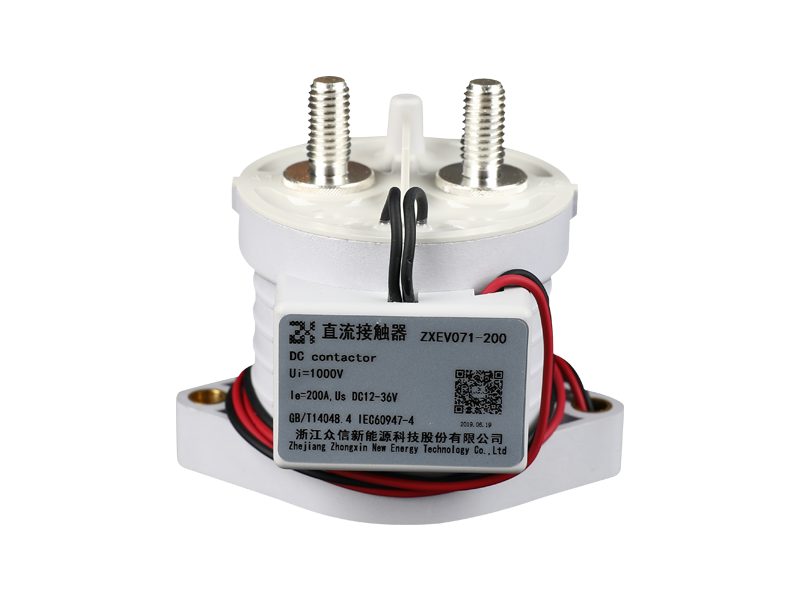

In modern electrical systems, the epoxy encapsulation medium pressure DC contactor plays a crucial role and is widely used in electric vehicles (EVs), energy storage systems (ESS), and photovoltaic (PV) installations. Its unique encapsulation technology enables performance in switching high-voltage DC currents, particularly in arc extinction under high-voltage DC conditions.

Epoxy encapsulation involves immersing the internal components of the contactor in high-performance epoxy resin, creating a robust protective layer. The key benefits include:

Superior Electrical Insulation: Epoxy resin has a high dielectric strength, effectively isolating electrical currents and reducing the risk of short circuits and electrical faults.

Outstanding Environmental Resistance: Encapsulated contactors are protected against dust, moisture, and corrosive gases, making them suitable for harsh operating environments.

Enhanced Mechanical Strength: Epoxy encapsulation provides additional structural support, improving resistance to vibration and mechanical shocks.

Switching high-voltage DC currents presents a major challenge due to arc formation and persistence. Epoxy encapsulation medium pressure DC contactors enhance arc extinction through the following mechanisms:

Nitrogen-Filled Arc Chambers: The arc chambers are filled with high-pressure nitrogen, which absorbs heat generated by the arc and accelerates arc quenching.

Magnetic Blowout Technology: Magnetic fields are designed to guide the arc path, stretching and cooling the arc to speed up extinction.

Thermal Stability of Epoxy Resin: Epoxy resin maintains stability under high temperatures, preventing performance degradation and ensuring continuous operation of the arc chamber.

With the development of high-voltage DC technology, the applications of epoxy encapsulation medium pressure DC contactors have expanded to:

Electric Vehicles (EVs): Contactors manage current flow between battery packs and motors, and the high arc extinction capability provided by epoxy encapsulation ensures the safety of the battery management system.

Energy Storage Systems (ESS): Contactors enable connection and disconnection of battery modules, with epoxy encapsulation improving system stability and service life.

Photovoltaic Systems: Contactors control current flow between solar panels and inverters, and encapsulation enhances resistance to environmental interference.

They are also used in electric forklifts, wind turbines, and power transmission systems.

Despite their advantages, epoxy encapsulation medium pressure DC contactors face several challenges:

Arc Extinction at Higher Voltages: Increasing system voltages make arcs more persistent, demanding improved extinction technology.

Thermal Stability of Encapsulation Materials: High temperatures can material aging or performance decline, affecting long-term reliability.

Balancing Size and Power Density: Maintaining high performance while reducing size and increasing power density remains a key design challenge.

Future trends include:

Integration of Multiple Arc-Extinction Technologies: Combining gas, magnetic, and liquid-cooled arc-extinction methods to enhance efficiency and reliability.

Development of High-Performance Encapsulation Materials: Materials with better thermal stability and anti-aging properties to extend contactor life.

Intelligent Monitoring and Control: Integration of sensors and control systems for real-time monitoring and fault prediction, improving safety and maintenance efficiency.

Epoxy encapsulation medium pressure DC contactors play a vital role in high-voltage DC systems thanks to their encapsulation and arc extinction capabilities. With ongoing technological advancements, their applications in EVs, ESS, and PV systems are expanding. Continuous innovation and research are key to enhancing performance and broadening the application scope.

Comparison of Epoxy Encapsulation Medium Pressure DC Contactors vs. Traditional Contactors

| Feature | Epoxy Encapsulation Medium Pressure DC Contactor | Traditional Contactor |

|---|---|---|

| Electrical Insulation | Excellent | Moderate |

| Environmental Resistance | Strong | Weak |

| Arc Extinction Capability | High | Low |

| Mechanical Strength | High | Medium |

| Service Life | Long | Short |

| Voltage Range | Medium | Low |

| Application Areas | EVs, ESS, PV systems | General Industry |

Epoxy encapsulation medium pressure DC contactors, as a key component in high-voltage DC systems, combine technical advantages with broad application potential, ensuring enhanced safety and reliability across modern electrical systems.