The performance advantages of magnetic latching relay are closely related to its working principle. The core operating mechanism of this relay is based on the synergy of electromagnet and permanent magnet. When the coil is connected to a DC pulse voltage, the magnetic field generated magnetizes the iron core, drives the contact to move, and realizes the circuit on and off. What is particularly important is that after the contact state is switched, even if the coil is powered off, the constant magnetic field generated by the permanent magnet and the hysteresis characteristics of the iron core can still maintain the current state of the contact without continuous power supply. This feature is the core difference between magnetic latching relay and traditional relays, and also lays the foundation for its advantages of low power consumption, high stability and long life.

Energy consumption revolution brought by power-off retention

The source of the low power consumption characteristics of magnetic latching relay is its unique power-off retention function. When maintaining the contact closed or open, traditional relays need to continuously supply power to the coil to maintain the magnetic field, thereby maintaining the stability of the contact, which makes the coil always in a power-consuming state, resulting in unnecessary energy loss. After the contact state of the magnetic latching relay is switched, the magnetic field generated by the permanent magnet independently maintains the contact position, and the coil does not need to be continuously energized. This "pulse control switching, permanent magnet maintenance state" working mode greatly reduces power consumption. Taking the circuit scenario that is in a long-term working state as an example, the magnetic latching relay only consumes power at the moment when the contact state changes, and almost no power is consumed at other times. Compared with traditional relays, it shows significant advantages in energy consumption and can effectively reduce the operating cost of equipment. At present, its energy-saving value is self-evident.

Solid guarantee of permanent magnetic magnetic field

Permanent magnets bring stability to the magnetic latching relay. In a complex and changeable electrical environment, traditional relays may cause the coil magnetic field to be unstable due to factors such as voltage fluctuations and electromagnetic interference, which in turn affects the contact state and causes circuit failure. The permanent magnet of the magnetic latching relay provides a stable and strong magnetic field to firmly fix the contact position after power failure. Even in the face of external voltage fluctuations, short power outages or electromagnetic interference, the magnetic field generated by the permanent magnet can still ensure that the contacts remain in their original state and are not easily disturbed by external factors. This stability enables the magnetic latching relay to operate reliably in scenarios such as power systems and communication base stations that require extremely high circuit stability, ensuring the continuous and stable operation of equipment and systems, greatly reducing the risk of system downtime caused by relay failures, and improving the reliability and safety of the entire electrical system.

The long-lasting way to reduce contact action

The long life characteristics of the magnetic latching relay also benefit from its working principle. Frequent contact action is one of the main reasons for the shortened life of traditional relays. Every time the contact is closed and opened, an arc is generated. The high temperature of the arc will burn the contact surface, causing contact wear. Over time, the contact performance will deteriorate and eventually cause the relay to fail. After the contact state switching of the magnetic latching relay is completed, the state is maintained by the permanent magnet without frequent action. This greatly reduces the number of times the contact contacts the arc, effectively reducing the wear and ablation of the contact. As the contact action frequency is reduced, the fatigue loss of mechanical components is also reduced accordingly, further extending the overall service life of the relay. In some application scenarios such as industrial automation equipment and smart meters that require long-term continuous operation, the magnetic latching relay reduces the frequency of equipment maintenance and replacement costs by virtue of its long life, thus improving the economy and reliability of the equipment.

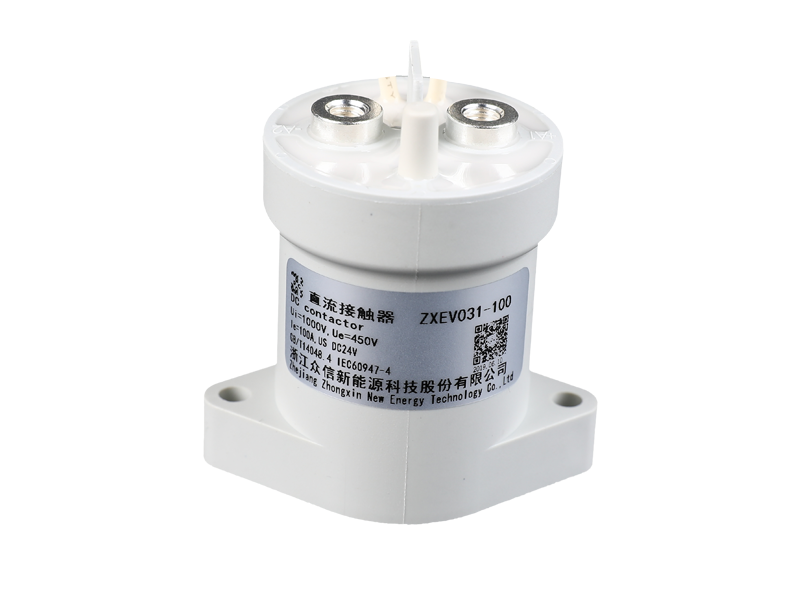

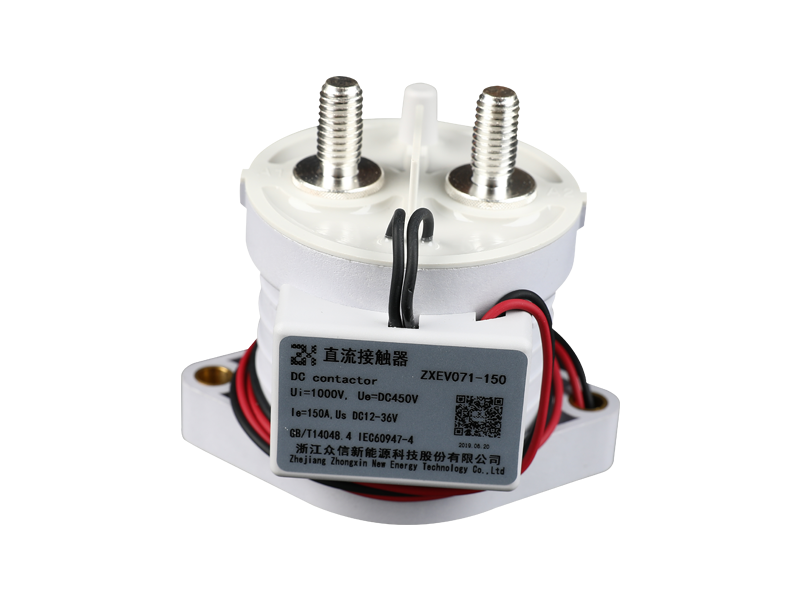

Performance advantages drive the expansion of diversified applications

The comprehensive advantages of low power consumption, high stability and long life of the magnetic latching relay make it widely used in many fields. In the field of power metering, the low power consumption characteristics meet the energy-saving needs of smart meters, reduce their own energy consumption, and improve metering accuracy; high stability and long life ensure the long-term stable operation of the meter and reduce maintenance costs. In the battery management system of new energy vehicles, the high stability of the magnetic latching relay can cope with the complex on-board electrical environment and ensure the reliability of battery charging and discharging control; the long life characteristics meet the long-term use needs of the car, reduce the frequency of relay replacement, and improve the overall safety of the system.