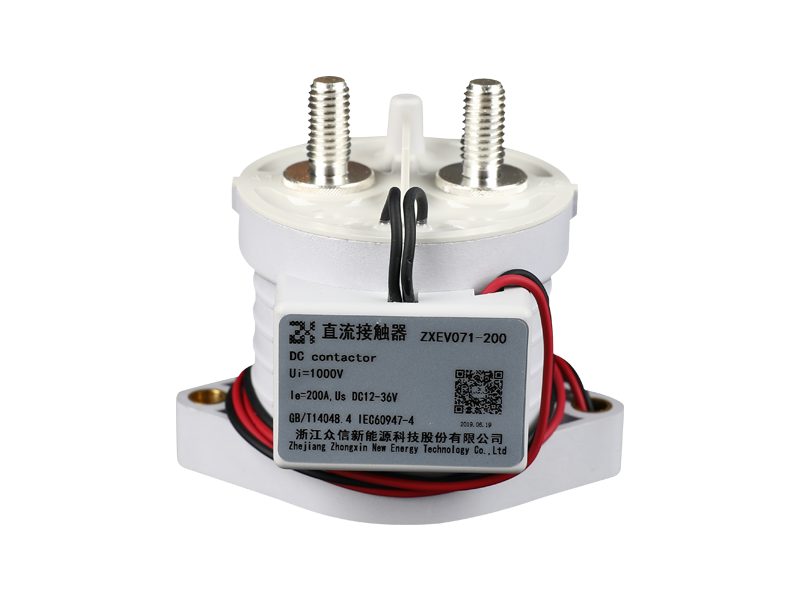

In the switching power supply system, the high-voltage DC relay achieves precise on-off control of the circuit by means of the electromagnetic drive mechanism. Its working principle contains precise electromagnetic and mechanical collaborative design, and becomes the key hub of power transmission and distribution.

Electromagnetic drive core mechanism

The switching power high voltage direct current relay uses electromagnetic drive as the core operation mode, and its working process can be divided into two stages: before excitation and after excitation. When the excitation voltage is not applied, the electromagnetic drive coil of the relay is in a state of no current, and the magnetic field cannot be formed inside the coil at this time. Under the action of the spring reaction force, the armature in the rotating mechanism maintains the initial position, so that the electrodes in the high-voltage cavity are stably connected through the contact piece, forming a closed loop to ensure that the circuit is in a conductive state. When the excitation voltage is applied to the electromagnetic drive part, the current begins to flow in the coil, and according to the principle of electromagnetic induction, the coil generates a corresponding magnetic field. The electromagnetic force generated by the magnetic field exceeds the spring reaction force, driving the armature to overcome the resistance and attract, and the movement of the armature drives the contact piece to rotate, so that the contact piece is separated from the original electrode and connected with the new electrode, thereby realizing the switching function of the circuit.

The internal mechanism of arc generation

In the process of switching power high voltage direct current relay to achieve circuit switching, the generation of arc is a physical phenomenon that cannot be ignored, especially when the contacts are disconnected. The inductor element in the circuit stores energy when the circuit is turned on. When the contacts are disconnected, the current changes sharply, and the energy stored in the inductor is released instantly, causing the voltage between the contacts to rise sharply. When the voltage between the contacts exceeds the breakdown voltage of the air, the air medium is ionized, and the originally insulating air is transformed into a conductive plasma channel, and the arc is generated. The high temperature and high energy characteristics of the arc will cause serious ablation of the contacts of the relay, causing the surface material of the contacts to gradually wear out, reducing the conductivity and mechanical strength of the contacts, and shortening the service life of the relay. The existence of the arc may also cause electrical interference, affect the normal operation of other electronic equipment, and may even cause serious safety accidents such as electrical fires, posing a great threat to the stability and safety of the entire switching power supply system.

Technical challenges of electromagnetic drive and arc control

The electromagnetic drive and arc control technologies of switching power high voltage direct current relay face many challenges. On the one hand, in order to ensure that the relay can quickly and accurately switch the circuit under different working conditions, the parameters of the electromagnetic drive part need to be carefully designed and optimized to achieve accurate matching of the electromagnetic force and the spring reaction force. On the other hand, in response to the arc problem, it is necessary to develop efficient arc extinguishing technology and protective measures. This not only involves the optimization design of the arc extinguishing chamber structure so that it can effectively suppress the expansion and continuation of the arc, but also requires the selection of suitable arc extinguishing gas in combination with the characteristics of the gas medium, and the use of the cooling and insulation characteristics of the gas to accelerate the extinguishing of the arc.

Technical optimization and future development direction

In order to meet the above challenges, the electromagnetic drive and arc control technology of high-voltage DC relays are developing in a more efficient and intelligent direction. In terms of electromagnetic drive, the application of new magnetic materials and optimized electromagnetic structure design can help improve the response speed and energy conversion efficiency of electromagnetic drive. In the field of arc control, in addition to continuously improving traditional arc extinguishing technology, such as optimizing the shape of the arc extinguishing chamber and improving the utilization efficiency of the arc extinguishing gas, new arc extinguishing concepts and technologies are constantly emerging. By introducing intelligent control algorithms, the working status and arc parameters of the relay are monitored in real time, and the arc extinguishing strategy is dynamically adjusted according to the actual situation to achieve precise arc extinguishing.