Electromagnetic relays remain fundamental components in modern electrical control systems, offering reliable switching performance in environments where precision, isolation, and operational safety are required. Although many forms of electronic switching devices have emerged, the electromagnetic relay continues to play a critical role in automation, power distribution, transportation, communication equipment, and industrial protection circuitry.

The reliance on electrical control and protection has increased across industries. Despite the introduction of solid-state switching devices, the electromagnetic relay remains widely used due to its ability to provide:

Its design allows a low-power control signal to manage a higher-power load, making the electromagnetic relay a cornerstone of modern industrial automation components and electrical distribution systems.

The electromagnetic relay converts electrical energy into mechanical motion through an interaction between a coil, magnetic field, armature, and fixed contacts. When current flows through the coil, it generates a magnetic field that pulls the armature toward the core. This motion opens or closes contacts, altering the state of the controlled circuit.

Coil Energization: The control signal energizes the relay coil.

Magnetic Field Formation: The energized coil produces a magnetic flux.

Armature Attraction: The magnetic field pulls the movable armature.

Contact Switching: Contacts open or close depending on relay configuration.

Return to Initial State: When the coil de-energizes, a spring mechanism returns the armature.

This electromagnetic-mechanical conversion ensures reliable switching even in environments requiring robust control circuit protection.

A well-designed electromagnetic relay incorporates multiple components engineered for durability, precision, and efficient magnetic performance.

| Component | Function | Notes |

|---|---|---|

| Coil | Generates magnetic flux when energized | Determined by rated coil voltage |

| Armature | Moves under magnetic force to actuate contacts | Must have low mechanical resistance |

| Core/Iron Frame | Guides and intensifies magnetic flux | Material affects sensitivity |

| Contacts | Conduct or interrupt electrical load | Can be NO, NC, or changeover |

| Return Spring | Restores armature when coil de-energizes | Influences release time |

| Yoke | Provides magnetic path between coil and armature | Impacts relay efficiency |

| Contact Terminals | Interface to controlled circuits | Requires reliable connection |

Each component works together to ensure accurate operation and switching performance.

Electromagnetic relay manufacturers offer a wide range of relay structures to meet the requirements of control panels, transportation systems, HVAC controls, communication networks, and power distribution equipment.

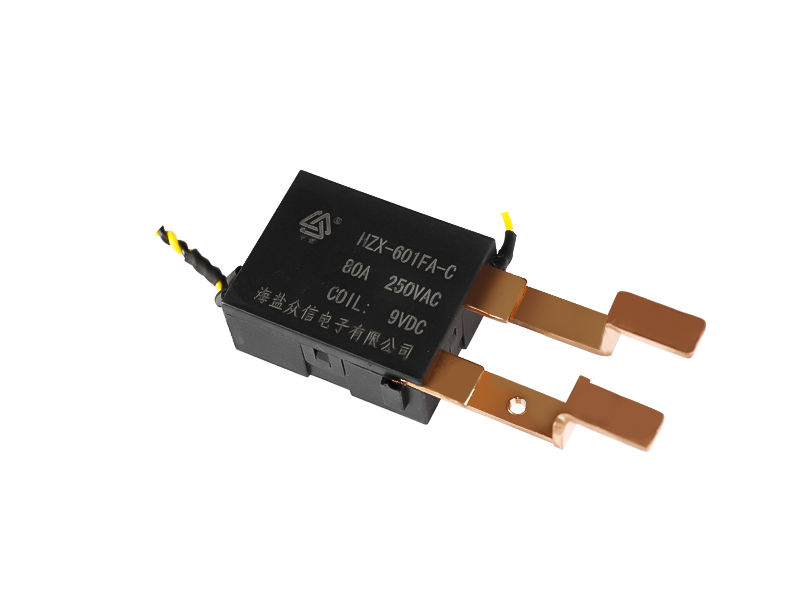

Power Relays

Suited for switching moderate to high-power loads in electrical distribution and industrial machines.

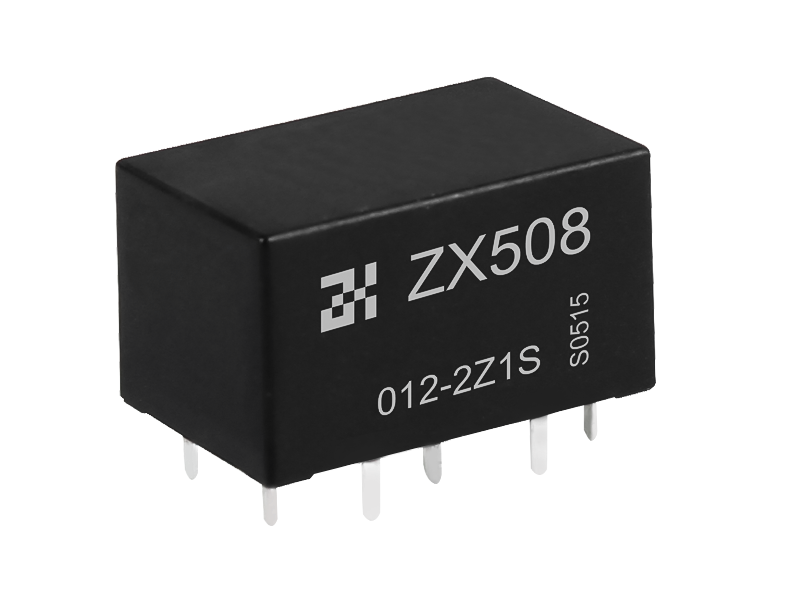

Signal Relays

Used for low-level control signals in instrumentation, automation systems, and communication devices.

Time-Delay Relays

Provide delayed switching using internal timing mechanisms, valuable in automation sequences.

Latching Relays

Maintain their state without continuous coil energization, improving energy efficiency.

Hermetically Sealed Relays

Protected against moisture, dust, and corrosive environments.

Each category addresses specific operational demands, aligning with the evolving requirements of industrial control systems and smart electrical infrastructure.

The switching capability of an electromagnetic relay depends on several mechanical and electrical characteristics, including:

Relay contacts are typically arranged in several forms:

NO (Normally Open)

NC (Normally Closed)

CO (Changeover / SPDT)

| Performance Factor | Description |

|---|---|

| Switching Voltage | Maximum allowable circuit voltage |

| Switching Current | Maximum load current the contacts can safely handle |

| Contact Resistance | Determines efficiency and heating behavior |

| Response Time | Speed of switching during energization and release |

| Electrical Life | Determined by load type and switching frequency |

| Mechanical Life | Number of operations without electrical load |

These specifications define how the relay performs in automation, protection, and distribution systems.

The coil represents the control side of the relay, and its characteristics determine how the device responds to electrical signals.

Common coil voltages include:

5 V

12 V

24 V

48 V

Higher industrial voltages depending on intended use

Coil resistance affects current draw and heat generation. Lower coil resistance yields faster actuation but higher power consumption. Optimized coil design allows manufacturers to deliver relays suited for energy-sensitive applications.

The material of the contact surface directly influences relay reliability. Key considerations include:

Hardness

Conductivity

Resistance to arc erosion

Suitability for different load types (inductive, resistive, capacitive)

Electromagnetic relay manufacturers commonly optimize contact materials to balance conductivity and longevity. Selecting the proper contact type enhances stability in electromechanical switching devices used across diverse industrial sectors.

Electromagnetic relays must withstand various external and operational stresses. Critical influences include:

Load type

Inrush current

Overvoltage transients

Switching frequency

Temperature variation

Humidity

Airborne debris

Vibration and mechanical shock

System layout, mounting orientation, and relay spacing affect thermal behavior and long-term reliability.

Despite the emergence of solid-state devices, electromagnetic relays retain several advantages:

Excellent electrical isolation

Strong surge resistance

Ability to handle overload conditions

Clear mechanical feedback

Long mechanical life

Compatibility with both AC and DC circuits

These strengths ensure continued demand across sectors requiring precise switching and dependable industrial automation components.

Choosing an appropriate relay requires evaluating performance criteria relevant to the intended application.

| Parameter | Importance | Evaluation Method |

|---|---|---|

| Load Type | Determines contact wear | Identify inductive or resistive load |

| Rated Contact Capacity | Ensures safe load switching | Compare with load |

| Coil Voltage | Must match control circuit | Verify supply stability |

| Switching Frequency | Affects mechanical life | Estimate operating cycles |

| Mounting Style | Impacts installation | Panel-mount or PCB-mount |

| Environmental Conditions | Dictates sealing requirements | Assess humidity, dust, vibration |

| Response Speed | Needed for precision control | Based on cycle timing |

Considering these factors helps engineers select reliable relays for long-term operation.

With global demand for high-efficiency switching expanding, electromagnetic relay manufacturers are accelerating innovation in areas such as:

Miniaturization for compact control panels

Enhanced sealing for moisture-prone environments

Low-power coil systems for energy-efficient equipment

Improved contact alloys for longer service life

Integration into smart automation platforms

Demand is also increasing in renewable energy systems, smart transportation, and distributed control architectures, all of which rely on precise relay operation.

Electromagnetic relays are applied across broad sectors, including:

Power distribution cabinets

Industrial automation lines

HVAC systems

Transportation and signaling equipment

Communication systems

Motor control and overload protection

Measurement and instrumentation systems

Their adaptability ensures stable performance in both low-voltage control circuits and higher-power distribution environments.

To ensure long-term reliability, relay installation must follow fundamental safety principles:

Correct matching of coil voltage

Proper load derating

Adequate ventilation for heat dissipation

Use of arc suppression circuits when needed

Routine inspection of contact wear

Correct system design ensures the relay operates within its intended limits, supporting long-term control circuit protection.

Electromagnetic relays remain indispensable components in electrical engineering, industrial automation, and control systems. Their ability to convert low-power control signals into reliable mechanical switching ensures they retain a vital role in environments requiring isolation, precision, and durable operation. As demand grows for compact, efficient, and high-performance switching components, electromagnetic relay manufacturers continue to refine coil systems, contact materials, and structural designs to meet modern application requirements.