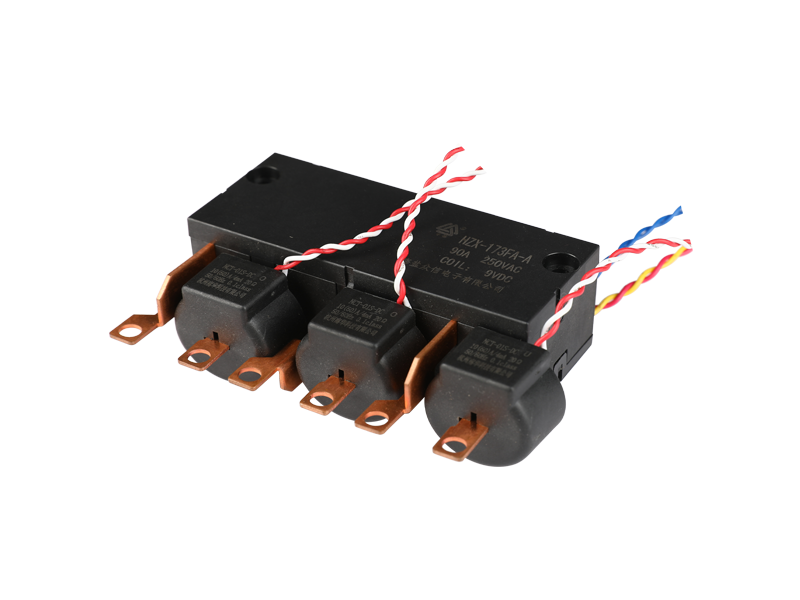

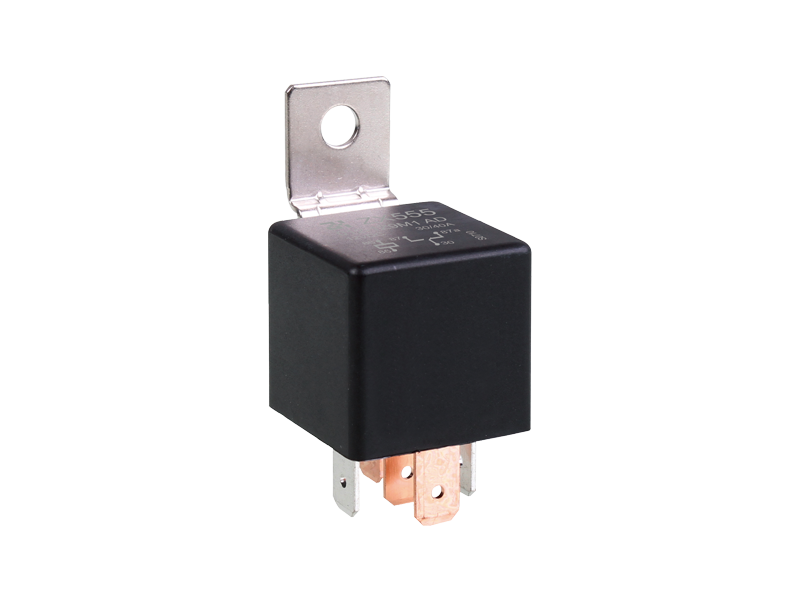

In high temperature environments, the working stability of

automotive relays is particularly critical. As an important part of the automotive circuit, the stability of relay performance is directly related to the safety and reliability of the entire automotive circuit. Therefore, how to ensure the working stability of relays under high temperature conditions has become an important issue in the automotive manufacturing and maintenance fields.

In a high temperature environment, the electronic components, coils and contacts inside the relay face huge challenges. To address these challenges, automotive relays are often manufactured using special high-temperature resistant insulating materials and engineering plastics. These materials have excellent thermal stability and mechanical strength and are able to maintain stable physical and chemical properties under high temperature conditions, ensuring that there is no deformation, melting or performance degradation inside the relay.

In addition to material selection, relay design is also key to ensuring its high-temperature stability. Optimizing thermal performance is an important part of the design process. For example, by optimizing the thermal conductivity of the electromagnet, the relay can effectively dissipate the heat generated inside the relay at high temperatures. At the same time, the shell design of the relay will also take heat dissipation needs into consideration, using structures such as ventilation holes and heat sinks to increase the heat dissipation area and improve heat dissipation efficiency.

The installation location and usage environment of automotive relays will also affect their high temperature stability. During installation, try to avoid placing the relay in high-temperature areas such as the engine compartment to reduce the impact of external heat sources. At the same time, for relays that work in high temperature environments for a long time, auxiliary heat dissipation measures such as installing a cooling fan or using insulation materials can be considered to further improve its working stability.

The working stability of automotive relays in high-temperature environments is a comprehensive issue that needs to be considered and solved from many aspects such as material selection, design optimization, installation location, and usage environment. Only in this way can we ensure that the relay can work stably under high temperature conditions and provide a strong guarantee for the safety and reliability of automotive circuits.