In today’s world of industrial automation, electrical control systems, and power distribution, relays play an essential role in controlling high-voltage circuits with low-voltage signals. Among the various types of relays available in the market, electromagnetic relays and solid-state relays are two of the widely used. Both serve similar purposes but have distinct operational characteristics and advantages.

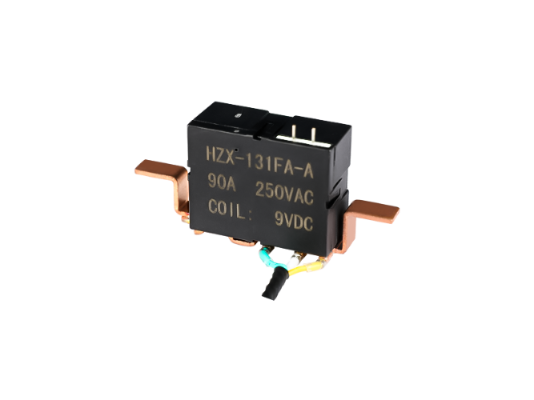

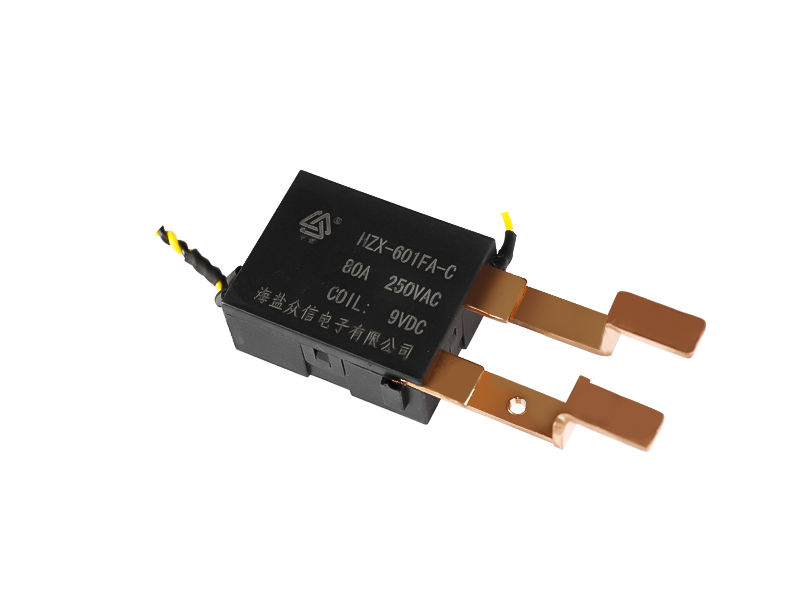

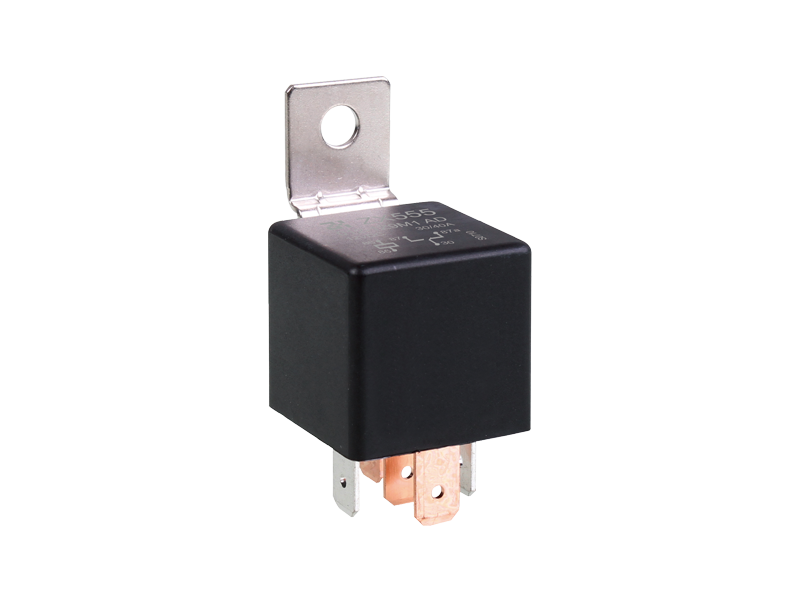

An electromagnetic relay is a type of electromechanical device used to control the opening or closing of electrical circuits. It operates by using an electromagnet to physically move a set of contacts, which either make or break the circuit connection. These relays are known for their reliability, cost-effectiveness, and relatively simple design.

Electromagnetic relays have been in use for many years, and their popularity stems from their durability and simplicity in design. However, they have certain limitations, such as mechanical wear over time and slower response times compared to solid-state relays.

A solid-state relay (SSR) is an electronic switching device that performs the same function as an electromagnetic relay but without moving parts. SSRs use semiconductor components like thyristors, triacs, or MOSFETs to switch the circuit on and off. Solid-state relays are prized for their ability to handle high-speed switching with no mechanical wear.

Solid-state relays offer enhanced reliability and longevity, as they do not rely on moving parts. Their ability to operate silently and switch at high speeds makes them ideal for applications where precision and durability are essential.

The choice between an electromagnetic relay and a solid-state relay depends on several factors, such as application requirements, budget, and environmental conditions. Below is a table comparing the two types based on key performance metrics.

| Feature | Electromagnetic Relay | Solid-State Relay |

|---|---|---|

| Switching Speed | Relatively slower, especially under heavy load | Faster, ideal for high-speed switching |

| Durability | Mechanical parts may wear over time | Long-lasting with no mechanical wear |

| Noise | Generates mechanical noise during operation | Silent operation |

| Size | Larger and bulkier | Compact and lightweight |

| Response Time | Longer response time due to mechanical components | Instantaneous response time |

| Power Consumption | Requires continuous power to maintain magnetization | Low power consumption |

| Price | Generally less expensive | Higher cost due to advanced components |

| Efficiency | Less efficient due to mechanical components | More efficient, with faster switching capabilities |

| Temperature Range | May be affected by temperature changes due to mechanical parts | Operates efficiently across a wider temperature range |

| Electrical Isolation | Typically lacks electrical isolation between control and load | Provides electrical isolation using optoisolators |

When selecting between an electromagnetic relay and a solid-state relay, consider the following factors:

Q1: How long do electromagnetic relays typically last?

Electromagnetic relays can last anywhere from 1 million to 10 million switching cycles, depending on the operating conditions and the quality of the components.

Q2: Can solid-state relays be used in high-voltage applications?

Yes, solid-state relays can handle high-voltage applications, but it is crucial to select the appropriate model that meets the specific voltage and current requirements of your system.

Q3: Do solid-state relays require any maintenance?

Solid-state relays require minimal maintenance due to the absence of moving parts. However, they may require occasional inspection, especially in high-power applications where heat buildup can occur.

Q4: Are there any safety concerns with using solid-state relays?

As with any electrical component, it is essential to ensure proper installation and cooling for solid-state relays, especially when dealing with high-power applications. Overheating can damage the relay.

Q5: Can I replace an electromagnetic relay with a solid-state relay in my existing system?

Yes, you can replace an electromagnetic relay with a solid-state relay, but it is important to check the specifications of the replacement SSR to ensure it can handle the same load and voltage requirements.

Choosing the right relay type is crucial to the performance and reliability of your electrical system. Electromagnetic relays offer a proven and cost-effective solution for many basic switching applications, while solid-state relays excel in high-speed, noise-sensitive, and high-performance applications. By understanding the differences and advantages of each, you can select the appropriate relay for your specific needs.