An electromagnetic relay is an electrically operated switch that uses an electromagnet to control the flow of current in a circuit. It acts as an interface between low-power control signals and high-power circuits, allowing a small current to control a much larger one. The fundamental mechanism involves a coil that, when energized, creates a magnetic field strong enough to move an armature and alter the position of electrical contacts.

The concept of the electromagnetic relay dates back to the early 19th century, emerging as a practical solution for signal amplification in telegraph systems. Over the decades, advancements in coil winding techniques, magnetic core materials, and insulation methods have refined its reliability and efficiency.

As industries transitioned toward automation and smart control systems, relay design evolved from purely mechanical constructions to hybrid and miniaturized versions, all aiming to reduce energy losses within the coil while maintaining strong magnetic performance.

Relays play a crucial role in electrical systems by providing isolation, signal amplification, and controlled switching between circuits of different power levels. From industrial automation to automotive and telecommunications, the relay ensures stable, repeatable control without direct human intervention.

In today’s context, energy efficiency has become an essential benchmark for relay selection. Reducing coil energy consumption not only lowers operational costs but also supports sustainability goals in large-scale industrial systems.

An electromagnetic relay comprises several key components that function in unison to achieve reliable electrical switching.

| Component | Function Description |

|---|---|

| Coil | Converts electrical energy into a magnetic field; its efficiency determines energy consumption and magnetic strength. |

| Armature | A movable iron lever that reacts to the magnetic field and changes contact positions. |

| Contacts (NO/NC) | Conduct or interrupt current depending on the armature’s movement; they define the relay’s switching state. |

When current passes through the coil, a magnetic field is generated around it. This field attracts the armature, causing it to pivot and change the position of the contacts—from normally open (NO) to closed, or vice versa. Once the current stops, the magnetic field collapses, and the armature returns to its initial position due to spring tension.

The efficiency of this magnetic action depends largely on the coil’s design, particularly the wire gauge, winding density, and magnetic core permeability. A high-efficiency coil generates the required magnetic force with reduced current, minimizing energy losses.

The control circuit sends a low-current signal to energize the coil.

The coil generates a magnetic field proportional to the current.

The armature, drawn toward the coil core, actuates the movable contacts.

The main circuit opens or closes based on the contact configuration.

When the control current stops, the magnetic field disappears, and the spring mechanism resets the contacts to their default state.

This process occurs within milliseconds, and improvements in coil efficiency directly enhance switching responsiveness while lowering thermal buildup and power draw.

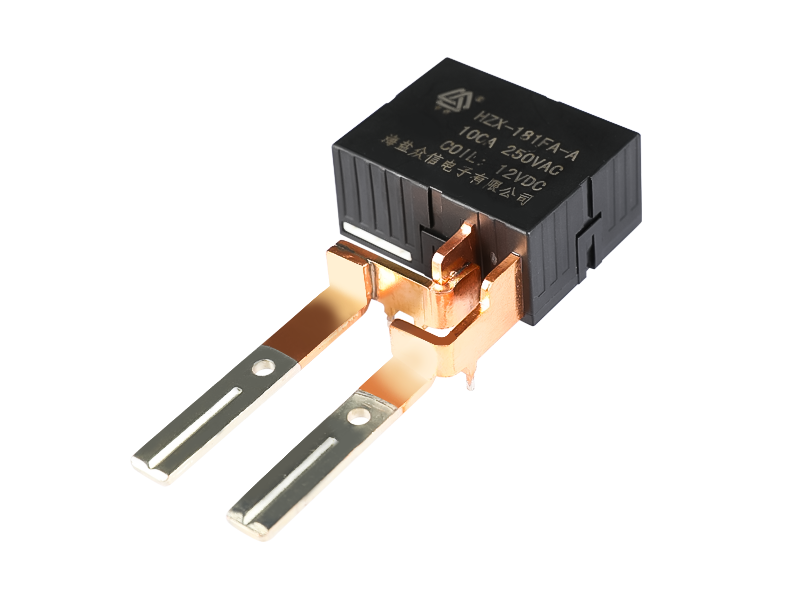

General-purpose electromagnetic relays are widely used in control panels, household appliances, and low-voltage industrial systems. These relays prioritize reliability and cost-effectiveness. In modern designs, coil efficiency improvements are achieved through the use of optimized copper windings and low-loss magnetic materials. The reduced coil power requirement allows these relays to remain active for long durations with minimal energy draw, supporting energy-conscious control systems.

In automotive systems, electromagnetic relay switches control lighting, fuel pumps, and ignition systems. Vehicles demand compact relays capable of enduring high vibration and temperature fluctuations. Enhanced coil efficiency reduces heat generation, stabilizing relay performance under continuous operation. The lower energy requirement also contributes to vehicle battery conservation and improved electrical system stability.

Protective relays are used in power distribution and automation to detect faults and trigger circuit isolation. Since these systems operate continuously, energy efficiency is critical. Advanced coil winding methods enable high magnetic sensitivity with low excitation power, ensuring quick fault response while minimizing total power usage across large-scale installations.

Time-delay electromagnetic relays are used where switching must occur after a preset interval. Their coils are engineered to maintain stable magnetization during the delay period without overheating. Efficiency optimization here is vital to prevent unnecessary energy losses during prolonged energization cycles.

These are the traditional electromagnetic relay type, utilizing a pivoted armature mechanism. Coil efficiency in these relays determines the magnitude of magnetic pull and the stability of contact closure. Modern armature relays use laminated cores and high-conductivity wire to minimize eddy current losses, improving energy performance.

Reed relays employ a hermetically sealed glass tube containing flexible metal reeds that serve as both armature and contacts. They require significantly less coil power due to their lightweight magnetic structure. High-efficiency reed relay coils are designed to produce precise magnetic flux with minimal energy input, making them ideal for signal-level switching in telecommunications and instrumentation.

(Note: While technically not electromagnetic, SSRs are often compared for context.)

Unlike electromagnetic relays, solid-state relays use semiconductor devices to perform switching without moving parts. Although SSRs eliminate mechanical wear and provide faster response times, they may exhibit higher leakage currents when off. Electromagnetic relay coils, in contrast, consume power only during actuation and offer complete electrical isolation, making them more energy-efficient in intermittent control applications.

Latching relays maintain their contact state after de-energization, requiring power only during the switching moment. This design significantly reduces coil energy consumption, aligning perfectly with energy-saving objectives. By using a dual-coil or magnetic retention structure, these relays minimize holding current, contributing to reduced system power budgets in automation and telecommunication networks.

| Relay Type | Coil Power Requirement | Energy Efficiency | Typical Application |

|---|---|---|---|

| General-Purpose Relay | Moderate | Medium | Control systems, consumer electronics |

| Automotive Relay | Low to Medium | High | Vehicle circuits, ignition systems |

| Protective Relay | Low | Very High | Power distribution, automation safety |

| Reed Relay | Very Low | Excellent | Telecommunication, measurement devices |

| Latching Relay | Minimal (momentary) | Exceptional | Memory circuits, energy-saving controls |

Each relay category demonstrates how coil efficiency directly impacts operational energy consumption, switching stability, and device longevity.

Understanding the key specifications of an electromagnetic relay is essential to evaluate its efficiency, especially regarding the coil’s role in energy saving. The following parameters directly influence how effectively the relay converts electrical energy into magnetic force while minimizing power losses.

The coil voltage represents the control signal level required to energize the electromagnetic relay. It determines the threshold at which magnetic flux is sufficient to move the armature and operate the contacts.

High-efficiency coils are designed to operate at lower current levels while maintaining the same pull-in force. This is achieved through optimized winding geometry and the use of materials with magnetic permeability. Reducing coil current not only saves energy but also lowers the thermal stress on insulation, thus extending the relay’s operating life.

Typical coil voltages include low-voltage DC options (5V, 12V, 24V) and AC variants (110V, 230V). However, the energy performance depends less on nominal voltage and more on how efficiently the coil converts electrical power into magnetic attraction.

Contacts define the relay’s ability to control external circuits. Their voltage and current ratings indicate how much electrical load they can safely switch. While contact performance primarily affects load management, it also relates indirectly to energy efficiency: stable contact operation prevents arcing and reduces unnecessary energy dissipation.

Energy-efficient electromagnetic relay switches use carefully balanced coil-to-contact ratios—ensuring that the magnetic force is strong enough to maintain contact pressure without overdriving the coil.

Response time indicates how quickly a relay reacts when energized or de-energized.

A high-efficiency coil with lower inductance achieves faster magnetization and demagnetization cycles, thereby improving response time while consuming less power.

| Specification | Description | Energy Impact |

|---|---|---|

| Pick-up Time | Duration to activate the relay after coil energization | Faster response minimizes transient losses |

| Drop-out Time | Duration to return to rest after de-energization | Shorter release prevents residual energy waste |

Insulation resistance refers to the ability of the relay to prevent current leakage between conductive parts and the coil. High insulation resistance ensures minimal parasitic losses, which improves energy utilization and safety. Efficient coil systems often use advanced enamel coatings and dielectric materials that maintain strong insulation with reduced thickness, contributing to compact and thermally stable designs.

Dielectric strength defines how much voltage the relay can withstand between its isolated components without breakdown. For energy-efficient designs, dielectric materials are chosen not only for voltage endurance but also for thermal performance. Improved dielectric strength prevents energy leakage, allowing the coil to operate with reduced power input while maintaining consistent performance under voltage fluctuations.

| Parameter | Typical Range | Design Significance | Energy Efficiency Benefit |

|---|---|---|---|

| Coil Voltage | 5V–230V (AC/DC) | Determines actuation threshold | Optimized voltage reduces wasted current |

| Coil Resistance | 50Ω–2kΩ | Defines current draw | Higher resistance lowers power loss |

| Pick-up Time | 5–15 ms | Activation speed | Lower inductance improves speed and efficiency |

| Drop-out Time | 3–10 ms | Deactivation speed | Faster return conserves energy |

| Contact Rating | Up to 30A, 250V | Load capacity | Balanced design prevents coil overdrive |

| Insulation Resistance | ≥100 MΩ | Leakage prevention | Reduces stray energy loss |

| Dielectric Strength | 1500–4000 V | Isolation endurance | Ensures efficient and safe operation |

Each parameter reveals the relationship between electromagnetic relay performance and coil energy optimization. Fine-tuning these characteristics allows engineers to achieve significant reductions in standby power and total energy consumption, particularly in industrial and automation systems where hundreds of relays operate continuously.

Electromagnetic relays are indispensable in diverse sectors due to their capability to provide electrical isolation, precise switching, and control flexibility. As energy efficiency becomes a central design priority, the role of coil efficiency in optimizing system performance and reducing overall power consumption has grown significantly.

In industrial automation, electromagnetic relays control machinery, conveyor systems, and process monitoring equipment. Large facilities may contain hundreds of relays operating simultaneously, meaning that coil efficiency directly affects the facility’s total energy load.

High-efficiency industrial electromagnetic relays utilize lightweight copper windings and improved magnetic cores that require less excitation current. This design allows continuous operation with reduced heat dissipation and minimizes the energy required to maintain contact engagement.

| Application Area | Typical Relay Function | Energy Efficiency Impact |

|---|---|---|

| Motor Control | Start/stop and overload protection | Reduced coil losses lower operating temperature |

| PLC Interfaces | Signal isolation between control and field devices | Low current draw improves system efficiency |

| Process Control Panels | Sequential or safety interlocking | Compact coils decrease standby energy use |

Through the optimization of coil design, industrial systems achieve stable operation even during prolonged duty cycles, contributing to both performance reliability and measurable energy reduction.

Automotive electrical systems depend heavily on electromagnetic relay switches for controlling circuits such as headlights, air conditioning, wipers, and fuel systems. In modern vehicles, where the electrical demand continues to rise, efficient power management is essential.

Relays with energy-saving coils reduce the electrical burden on the vehicle’s power supply, particularly during engine-off or idle states when power conservation is crucial. DC electromagnetic relays with optimized coil winding minimize current consumption while maintaining quick actuation, enhancing both response precision and system longevity.

In telecommunication systems, electromagnetic relays are used for signal routing, line protection, and circuit switching. These applications require rapid, precise, and energy-efficient operation due to continuous service demands.

High-efficiency reed relays are often employed here, as their minimal coil current and fast response characteristics are ideal for low-power signal switching. The low coil power requirement also reduces the heat load within compact network enclosures, improving stability and reducing cooling needs—an indirect yet important aspect of energy conservation.

In consumer electronics, relays manage power supply switching, battery protection, and standby control. Devices such as air conditioners, washing machines, and smart home appliances benefit from relays that consume less energy when idle or in low-power modes.

By integrating coils that operate efficiently at low voltages, these relays contribute to the overall energy efficiency ratings of household devices. This design approach supports compliance with international energy-saving standards while maintaining reliability under frequent operation.

In power systems and substations, protective electromagnetic relays are critical for fault detection and circuit isolation. They must operate continuously to monitor system conditions, making coil efficiency paramount to long-term energy savings.

A small improvement in coil design can yield substantial energy reduction when multiplied across thousands of relays installed in large distribution networks. Additionally, efficient coil insulation reduces temperature rise, enhancing relay sensitivity and long-term stability under continuous current monitoring.

| Field | Relay Type | Function | Coil Efficiency Advantage |

|---|---|---|---|

| Industrial Control | General-purpose relay | Power line switching | Low coil current reduces heat losses |

| Automotive | DC electromagnetic relay | Circuit activation | Saves battery power and extends relay life |

| Telecommunication | Reed relay | Signal transmission | Minimal coil power enables fast response |

| Power Distribution | Protective relay | Fault isolation | Continuous operation with low energy draw |

Electromagnetic relays offer a unique combination of operational reliability, electrical isolation, and energy efficiency—particularly when designed with optimized coils. Understanding both the advantages and limitations helps engineers make informed choices for specific applications.

Electrical Isolation

High Current/Voltage Switching Capability

Simple to Use

Mechanical Wear and Tear

Slower Switching Speed Compared to SSRs

Contact Bounce

| Feature | Benefit | Limitation | Energy Efficiency Role |

|---|---|---|---|

| Electrical Isolation | Protects control circuits | N/A | Maintains isolation with low coil current |

| High Voltage/Current Switching | Supports industrial loads | Mechanical stress on contacts | Optimized coils reduce power losses |

| Mechanical Simplicity | Easy integration | Wear over time | Reduced heat improves lifespan |

| Switching Speed | Adequate for applications | Slower than SSRs | Low inductance coils enhance response without extra power |

| Contact Reliability | Stable operation | Bounce can occur | Efficient coil ensures strong contact closure |

Through proper design, electromagnetic relays with energy-saving coils strike a balance between performance, operational reliability, and reduced power consumption. In applications where energy efficiency is critical, such relays provide a cost-effective and technically viable solution compared to continuous high-power alternatives.

While both electromagnetic relays and solid-state relays (SSRs) are widely used for electrical switching, their operating principles, energy consumption, and application suitability differ significantly.

| Feature | Electromagnetic Relay | Solid-State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Mechanical armature actuated by coil magnetic field | Semiconductor devices (triacs, MOSFETs) perform switching |

| Electrical Isolation | Complete galvanic isolation | Isolation typically via optical coupling |

| Energy Consumption | Coil consumes power only during actuation (or briefly in latching designs) | Continuous minimal standby leakage current |

| Response Speed | Milliseconds; limited by mechanical motion | Microseconds to milliseconds; faster switching |

| Load Types | AC or DC; high current/voltage handling | AC or DC; limited by semiconductor ratings |

Faster Switching: SSRs provide near-instantaneous actuation, suitable for high-speed control applications.

No Mechanical Wear: Absence of moving parts eliminates contact degradation, making SSRs ideal for high-frequency switching.

Compact Form Factor: SSRs can be smaller than equivalent electromagnetic relays in certain voltage/current ranges.

Lower Power Consumption During Operation: High-efficiency coils allow electromagnetic relays to consume minimal energy, especially in latching or momentary designs.

Complete Electrical Isolation: Galvanic isolation is inherent, reducing leakage concerns.

High Current/Voltage Switching: EM relays can handle higher instantaneous currents and voltages than many SSRs of similar size.

Cost-Effective for Intermittent Loads: When switching occurs infrequently, energy savings from efficient coils outweigh the initial costs.

Electromagnetic Relay: Optimal for systems requiring high current or voltage switching, electrical isolation, or energy-efficient intermittent operation. Examples include industrial automation panels, protective circuits in power distribution, and battery-operated systems.

Solid-State Relay: Preferred for ultra-fast switching, high-frequency control, or environments where mechanical wear must be minimized, such as instrumentation or high-speed signal routing.

In energy-conscious designs, electromagnetic relays with optimized coils often provide the compromise between operational reliability and minimal energy consumption, making them indispensable in modern industrial, automotive, and telecommunication applications.

A relay may fail to activate if the coil receives insufficient voltage or current. In high-efficiency coil designs, this can occur due to:

Undersized power supply or voltage drops in long control circuits

Loose connections or corroded terminals

Magnetic core saturation from external fields

Energy-saving consideration: Ensuring the coil receives its designed excitation voltage maximizes magnetic efficiency without overdriving the coil, preventing excessive energy consumption and heat buildup.

Contacts may fail to actuate fully due to mechanical obstruction, worn springs, or insufficient magnetic pull. Optimized coils generate enough force with minimal current, but even efficient designs require proper armature alignment.

Regular inspection of contact integrity and lubrication (if applicable)

Verification of coil excitation voltage to maintain sufficient magnetic force

Energy-saving impact: Proper contact operation avoids repeated attempts to actuate the relay, reducing wasted electrical energy.

Audible clicking or mechanical vibration can result from loose armature or contact components. While high-efficiency coils reduce thermal stress and help maintain stable actuation, mechanical issues can still propagate energy losses through unnecessary oscillations.

Mitigation: Tightening mechanical fixtures and ensuring correct coil positioning minimizes mechanical energy waste and maintains magnetic coupling.

Even low-power coils can generate heat during prolonged operation. In designs focusing on coil efficiency:

Laminated cores reduce eddy current losses

Low-resistance windings minimize Joule heating

Optimized duty cycles prevent excessive continuous energization

Energy-saving benefit: Controlling coil temperature reduces resistive losses and prolongs relay life, ensuring that energy is converted efficiently into mechanical motion rather than heat.

| Issue | Potential Cause | Recommended Solution | Energy Efficiency Benefit |

|---|---|---|---|

| Relay Not Activating | Low voltage/current | Verify supply and connections | Ensures coil uses minimal energy effectively |

| Contacts Not Closing | Mechanical obstruction or weak magnetic force | Adjust armature, check coil excitation | Reduces repeated actuation losses |

| Excessive Noise | Loose armature or vibrations | Tighten assembly, optimize coil placement | Maintains efficient magnetic transfer |

| Overheating | Continuous energization, high resistance | Use laminated cores, low-resistance windings | Minimizes energy wasted as heat |

The field of electromagnetic relays continues to evolve, driven by demands for energy efficiency, miniaturization, and intelligent control. Innovations focusing on coil efficiency and energy saving are central to the next generation of relay technology.

As electronic systems become more compact, there is a growing demand for smaller electromagnetic relays that retain high switching capacity. Miniaturized relays require coils that generate sufficient magnetic force in limited space. Advances in:

High-permeability magnetic materials

Optimized micro-winding techniques

Reduced coil resistance

enable compact designs without increasing power consumption. Smaller, energy-efficient coils also reduce thermal load, supporting longer life spans and stable operation in dense control panels.

Future relays will increasingly integrate sensors and digital monitoring capabilities to optimize energy use:

Coil current sensors track real-time energy consumption

Temperature and vibration sensors prevent inefficiencies caused by overheating or misalignment

Digital control interfaces adjust coil energization to match load requirements

These innovations allow electromagnetic relays to actively manage energy, reducing unnecessary power draw while maintaining reliable switching and protecting downstream circuits.

Enhancements in coil wire materials, insulation, and core laminations continue to improve energy efficiency. High-conductivity wire reduces resistive losses, while advanced insulation prevents leakage currents. Similarly, optimized contact designs:

Ensure strong closure with lower magnetic force

Minimize bounce and arcing

Extend operational life

By combining material improvements with precision engineering, relays can deliver performance at lower energy costs, meeting the needs of industrial, automotive, and telecommunications sectors.

| Feature | Technical Innovation | Energy Saving Advantage |

|---|---|---|

| Miniaturization | High-permeability cores, compact windings | Maintains magnetic force with less power |

| Smart Monitoring | Sensors for current, temperature, vibration | Reduces unnecessary coil energization |

| Advanced Materials | Low-resistance wire, improved insulation | Minimizes energy losses and thermal buildup |

| Optimized Contacts | Reduced bounce, precise closure | Prevents repeated actuation and energy waste |

Electromagnetic relays remain a cornerstone of electrical and electronic systems, providing reliable switching, electrical isolation, and the ability to handle high currents and voltages. Over the decades, the evolution of relay design has increasingly focused on coil efficiency and energy saving, reflecting both industrial and environmental priorities.

Optimized coils reduce the current required for actuation, minimize heat generation, and extend the operational life of the relay. This not only enhances performance in industrial automation, automotive systems, telecommunications, consumer electronics, and power distribution, but also contributes to overall energy efficiency in large-scale installations.