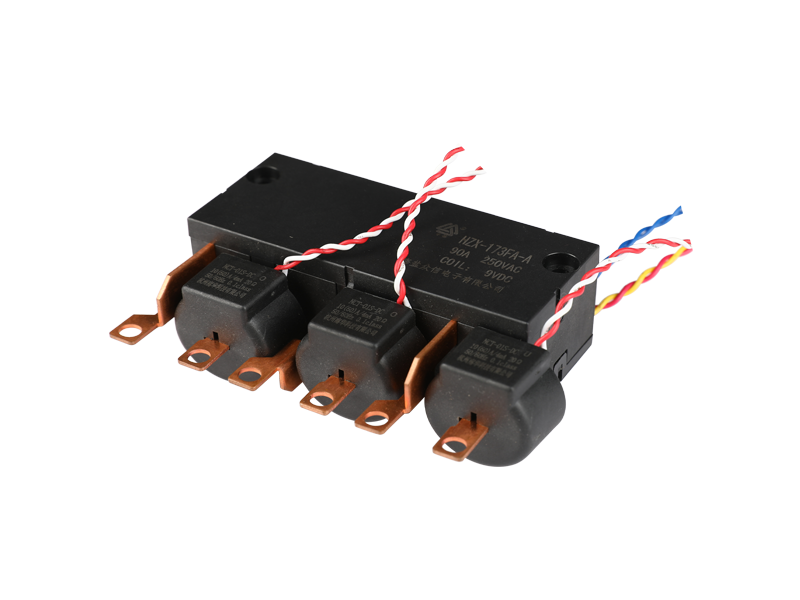

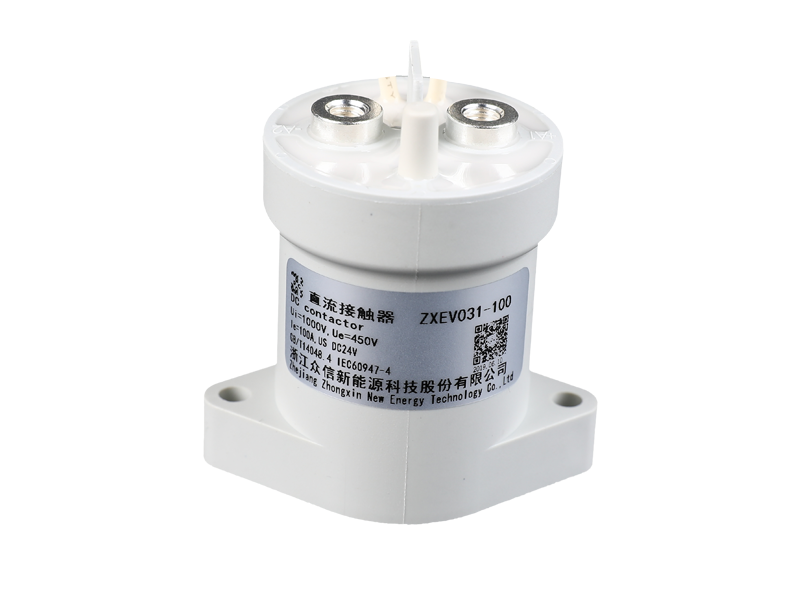

As a key component in the electrical control field, the core advantage of a magnetic latching relay for synchronous switches lies in its unique "magnetic latching" characteristic. Structurally, the core components of a magnetic latching relay include a coil, core, permanent magnet, armature, and contact assembly. The precise coordination of these components forms the physical basis for its "magnetic latching" characteristic. The coil, as the source of electromagnetic force, is typically wound with high-conductivity wire, enabling rapid magnetic field generation when current is applied. The core, made of a material with magnetic conductivity, guides the magnetic field path, enhances its intensity, and ensures effective transmission of the electromagnetic force. The permanent magnet is key to the "magnetic latching" characteristic, providing a stable inherent magnetic field and continuous magnetic support to maintain the armature's position. The armature, as the intermediate component connecting the magnetic field and the contact operation, is made of a material that balances magnetic permeability and mechanical strength, ensuring flexible movement under the influence of the magnetic field. The contact assembly directly handles the circuit switching function, and its contact performance and durability directly impact the overall reliability of the relay.

Dynamic Interaction Mechanism of Electromagnetic and Permanent Magnetic Forces

The operation of a magnetic latching relay for synchronous switches is essentially a process of interaction and dynamic balance between electromagnetic and permanent magnetic forces. When a positive pulse current flows through the coil, it generates a magnetic field around the core. The direction of this magnetic field follows the right-hand screw rule of electromagnetic induction, and its magnitude is related to the intensity and duration of the pulse current. The electromagnetic field generated by the coil and the inherent magnetic field of the permanent magnet superimpose in space. Because magnetic fields of the same polarity repel each other and opposite polarities attract each other, the superposition of these two magnetic fields causes the intensity and direction of the resulting magnetic field to change significantly. When the force of the resulting magnetic field is sufficient to overcome the inertia of the armature and the resistance of the reaction device, the armature moves in a specific direction, driving the contact assembly to close and completing the circuit. The permanent magnet plays a crucial role in this process. When the positive pulse current disappears, the electromagnetic field generated by the coil dissipates, but the inherent magnetic field of the permanent magnet remains, generating a continuous magnetic force on the armature, keeping the armature in the closed contact position and maintaining the circuit connection without the need for continuous power to the coil. This "power-off hold" phenomenon is a direct demonstration of the "magnetic latching" characteristic. It stands in stark contrast to the operating mode of traditional relays, which require continuous current to maintain the contact state, significantly reducing the product's energy consumption.

The Reverse Switching Principle of the "Magnetic Latching" Characteristic

When the circuit needs to be disconnected, the magnetic latching relay for synchronous switches switches state by applying a reverse pulse current to the coil. The direction of the magnetic field generated by the reverse pulse current is opposite to that of the forward current. At this time, the coil magnetic field and the permanent magnet's inherent magnetic field shift from superposition to mutual cancellation, and the strength of the resulting magnetic field rapidly decreases or even reverses. When the force generated by the resulting magnetic field is less than the return force of the reaction device, the armature moves in the opposite direction under the reaction force, causing the contact assembly to open and the circuit to terminate. After the reverse pulse current disappears, the permanent magnet's inherent magnetic field holds the armature in the open contact position, further demonstrating the "magnetic latching" characteristic. This operating mechanism, which uses pulsed current to control state switching and permanent magnets to maintain the state, means that the magnetic latching relay for synchronous switches requires only a brief pulse of current during state switching and consumes almost no energy during the state-holding phase, significantly improving the product's energy efficiency. Due to the short duration of the pulse current, coil heating is effectively controlled, extending the product's service life.

The "Magnetic Latching" Feature Supports Synchronous Control

In synchronous switching applications, the "magnetic latching" feature provides a stable foundation for precise synchronous control. Synchronous control requires that the relay's contacts open and close at specific power phases to prevent inrush currents and arcing in the circuit. The "magnetic latching" feature ensures that the relay remains stable after state switching without the need for continuous power supply. This reduces the interference of continuous current on the magnetic field, ensuring that the contact state remains stable after the synchronous operation is completed, preventing unexpected changes due to power supply fluctuations. The "magnetic latching" feature ensures that the relay contacts remain stably in the open and closed state after the synchronous operation is completed, ensuring that the capacitor switching effect meets synchronous control requirements and preventing circuit failures caused by unexpected contact operation.