The automotive industry has witnessed significant advancements in electric vehicle (EV) design over the past decade, driven by the growing demand for higher efficiency and safer energy systems. Among the core components enabling reliable EV operation are medium pressure 450VDC automotive DC contactor relays. These devices play a pivotal role in controlling high-voltage circuits, ensuring the safe connection and disconnection of batteries, and protecting sensitive electrical components from transient surges and faults. A key feature that has recently garnered attention is the insulation performance of these contactor relays, which directly influences system safety, longevity, and operational stability.

Insulation in medium pressure 450VDC automotive DC contactor relays is designed to withstand high DC voltage without degradation over time. In high-voltage electric vehicle applications, consistent insulation prevents accidental shorts, arc formation, and potential thermal damage, which are critical for both vehicle performance and passenger safety. The evolution of insulating materials, combined with precise engineering of relay components, ensures that these devices maintain dielectric strength under demanding environmental conditions such as high temperature, vibration, and humidity.

| Parameter | Value / Specification | Remarks |

|---|---|---|

| Rated DC Voltage | 450 VDC | Medium pressure classification |

| Insulation Resistance | >100 MΩ | Measured at standard test voltage |

| Dielectric Strength | 2.5 kV AC for 1 min | Ensures no breakdown under stress |

| Operating Temperature Range | -40°C to 85°C | Suitable for automotive conditions |

| Vibration Resistance | 10–55 Hz, 1.5 mm amplitude | Ensures performance in harsh terrain |

| Humidity Resistance | 95% RH, non-condensing | Prevents moisture-induced faults |

The integration of medium pressure 450VDC automotive DC contactor relays in EVs has highlighted the importance of consistent insulation performance for battery management systems (BMS). By maintaining high insulation resistance, the relays minimize leakage currents, ensuring that the vehicle’s energy efficiency is not compromised. Furthermore, insulation contributes to longer service life of the relay and adjacent electrical components, reducing maintenance intervals and enhancing overall reliability.

In modern EV architectures, the relays are often employed in series with other high-voltage components such as DC-DC converters, inverters, and battery packs. High insulation strength ensures that even under voltage spikes, the relay can safely interrupt current without causing arcing or electrical stress to surrounding components. Additionally, insulation performance is closely tied to electromagnetic compatibility, preventing interference with sensitive automotive electronics.

The adoption of advanced insulating materials, including high-grade polymers and reinforced epoxy resins, has revolutionized the performance of automotive DC contactor relays. These materials provide dielectric properties, mechanical robustness, and thermal stability. For medium pressure 450VDC applications, the combination of such materials with precise relay design ensures that both safety and efficiency are optimized. Designers can leverage these innovations to meet stringent automotive safety standards, including ISO 6469 for electric vehicles and international standards for high-voltage electrical safety.

Environmental factors also play a critical role in determining insulation requirements. Electric vehicles operate across a wide range of climates, from extremely cold regions to hot and humid environments. Medium pressure 450VDC automotive DC contactor relays are tested rigorously under these conditions to ensure that insulation integrity is maintained throughout the vehicle’s lifecycle. The relays must withstand thermal cycling, vibration, and exposure to moisture while continuing to provide reliable operation.

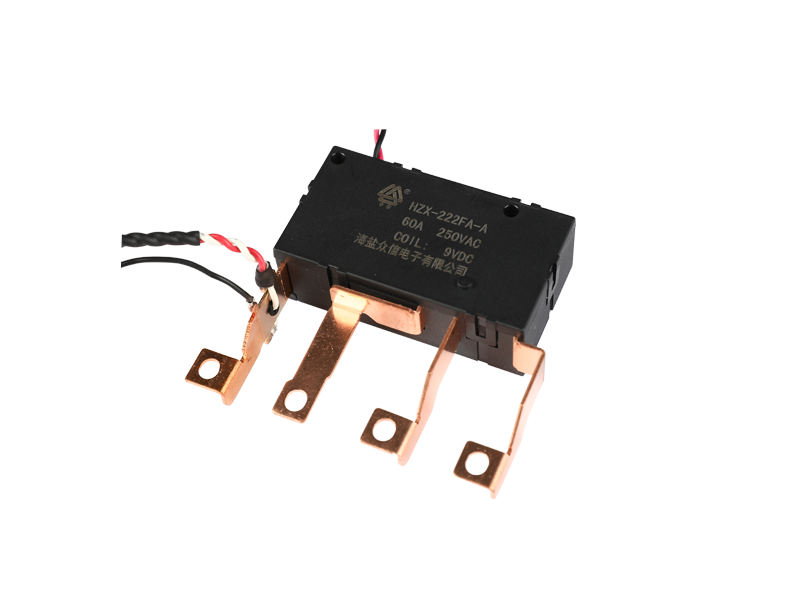

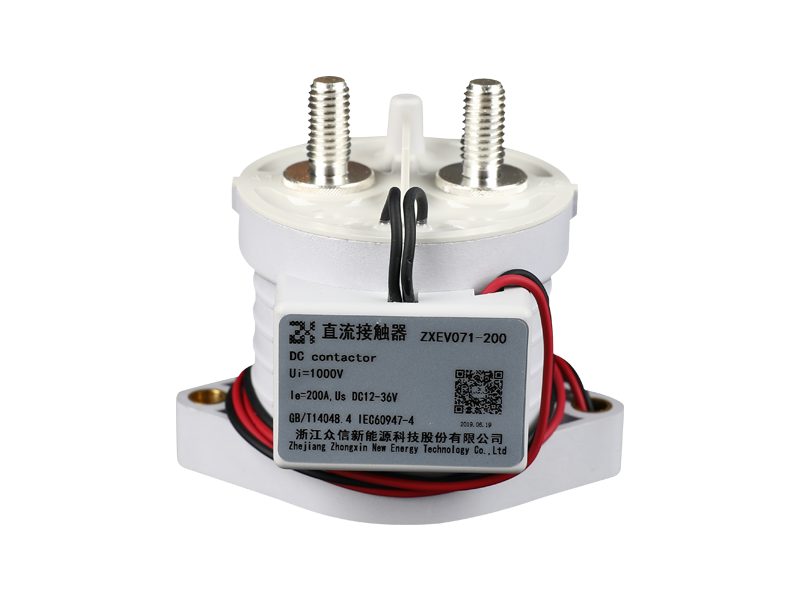

Recent developments in relay engineering have focused on improving insulation performance while maintaining compact size and high current-carrying capability. Medium pressure 450VDC automotive DC contactor relays now incorporate precision-engineered contacts, optimized coil designs, and reinforced insulating housings. These enhancements allow the relay to handle both high DC voltages and transient spikes without compromising operational integrity.

One notable innovation is the use of epoxy encapsulation in the relay body. This method provides uniform insulation coverage and resistance to environmental stress. Unlike conventional designs, encapsulated relays can endure harsher conditions, including rapid temperature cycling and mechanical vibration, making them suitable for modern electric vehicles operating in varied terrains.

| Feature | Standard Relay Specification | Advanced Insulation Relay | Benefits |

|---|---|---|---|

| Encapsulation Type | None / Minimal | Epoxy Resin Encapsulation | Enhanced dielectric strength |

| Contact Material | Copper Alloy | Silver-plated Copper Alloy | Lower contact resistance, improved reliability |

| Coil Insulation Class | Class B | Class F / H | Higher thermal tolerance |

| Vibration Resistance | 5–55 Hz, 1 mm amplitude | 10–55 Hz, 1.5 mm amplitude | More stable in rough conditions |

| Operating Temperature Range | -20°C to 70°C | -40°C to 85°C | Expanded environmental adaptability |

Medium pressure 450VDC automotive DC contactor relays are integral in various EV subsystems. They are commonly used in battery management systems (BMS), pre-charge circuits, main battery disconnects, and high-voltage safety interlocks. High insulation performance ensures that the relay can reliably operate without leakage currents or electrical arcing, even during high-power switching events.

In battery management systems, maintaining high insulation resistance reduces energy loss and prevents inadvertent discharge, thereby enhancing overall efficiency. In pre-charge circuits, the relay safely manages the inrush current when connecting the battery to the inverter, preventing damage to semiconductors and other critical components. High dielectric strength also contributes to vehicle safety by preventing short circuits and electrical faults.

The performance of medium pressure 450VDC automotive DC contactor relays is heavily influenced by the choice of materials and internal design. High-grade polymers and reinforced epoxy resins provide the necessary dielectric properties while also resisting thermal degradation. Contact materials, such as silver-plated copper alloys, improve conductivity and reduce wear during repeated switching cycles.

Environmental resilience is equally important. Electric vehicles often operate in climates, where relays are exposed to moisture, dust, and vibrations. Modern relays undergo rigorous testing, including thermal cycling, high-humidity exposure, and mechanical shock, to ensure that insulation performance remains consistent over the vehicle’s lifetime. These design considerations align with industry safety standards, such as ISO 6469, which governs high-voltage systems in EVs.

| Environmental Factor | Requirement / Test Condition | Purpose |

|---|---|---|

| Temperature Cycling | -40°C to 85°C, 50 cycles | Ensures insulation stability |

| Humidity Resistance | 95% RH, non-condensing | Prevents moisture-induced failure |

| Vibration | 10–55 Hz, 1.5 mm amplitude | Maintains reliable operation in vehicles |

| Mechanical Shock | 50 g, 11 ms pulse | Verifies durability under impact |

| Electrical Overstress | 1.5 × rated voltage, 1 sec | Confirms dielectric withstand capability |

As electric vehicles continue to proliferate globally, the demand for reliable high-voltage components like medium pressure 450VDC automotive DC contactor relays is expected to grow. Insulation performance remains a critical differentiator, influencing both safety and efficiency. Engineers are increasingly focused on integrating advanced materials, optimizing contact and coil designs, and employing encapsulation techniques to meet rising performance expectations.

Additionally, regulatory standards and consumer safety concerns are pushing manufacturers to prioritize insulation reliability. Enhanced insulation not only reduces the risk of electrical faults but also improves energy efficiency by minimizing leakage currents. This directly supports longer battery life, fewer maintenance requirements, and safer operation, aligning with the broader sustainability goals of the EV industry.

Medium pressure 450VDC automotive DC contactor relays have evolved beyond simple switching devices to critical components that ensure safety, efficiency, and reliability in modern electric vehicles. By focusing on insulation performance, engineers can achieve high dielectric strength, resistance to environmental stress, and long-term operational stability. These attributes make the relays indispensable in battery management systems, pre-charge circuits, and high-voltage safety networks. The integration of epoxy encapsulation, advanced contact materials, and robust environmental testing positions these relays as essential for the next generation of electric vehicles.