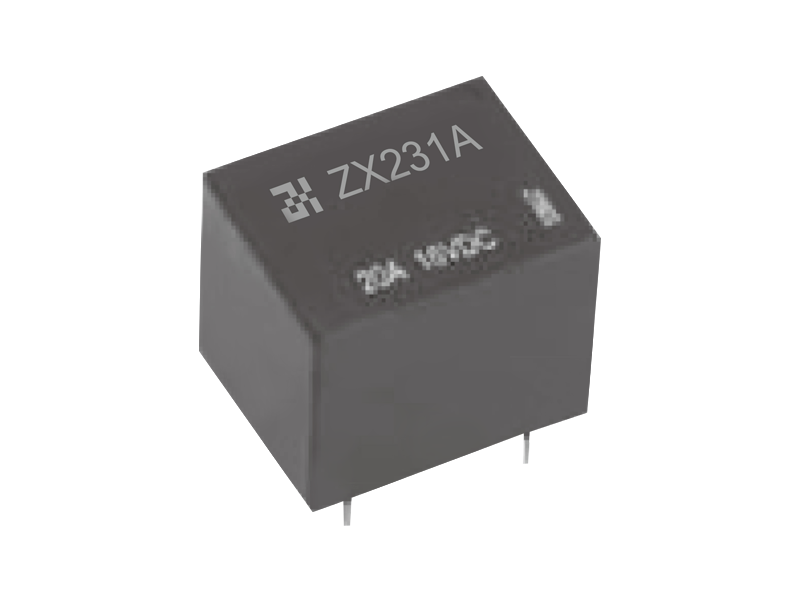

Ceramic high-voltage DC contactors are electrical devices that can be used in high-voltage and high-temperature environments, and play an important role in industry, power systems, and other fields. The contact material of such contactors usually uses alumina ceramics, which have high-voltage resistance, high insulation performance, good mechanical strength, and chemical stability.

Alumina ceramic is a high-strength material that can withstand high-pressure environments. In ceramic high-voltage DC contactors, current passes through the contacts, so the contacts must be able to withstand the high pressure of the current. Alumina ceramics have high mechanical strength and can effectively withstand the pressure and stress caused by high pressure, ensuring the normal operation of the contactor.

Alumina ceramics have high insulating properties. In electrical equipment, insulating properties are very important, especially in high-voltage environments. Alumina ceramics have good insulating properties and can effectively block the flow of current, avoiding current leakage and short-circuiting. This excellent insulating property can ensure the safety and reliability of contactors.

Alumina ceramics also have good chemical stability. In the working environment of high-voltage DC contactors, there may be various chemicals such as humidity and corrosive gases. Alumina ceramics have corrosion resistance and can withstand the erosion of various chemicals without chemical reactions and material damage.

The contact material of the ceramic high-voltage DC contactor uses alumina ceramic because it has high voltage resistance, high insulation performance, good mechanical strength, and chemical stability. This material can ensure the normal operation of the contactor under high-voltage and high-temperature environments, improving the safety and reliability of the equipment.