As the demand for clean and efficient energy continues to grow, high voltage direct current (HVDC) technology has emerged as a crucial component in the modern power grid. HVDC transmission enables efficient long-distance power transfer, interconnecting renewable energy sources, and stabilizing the grid. Within this domain, ceramic high voltage direct current contactors (CHVDC contactors) have gained prominence for their unique properties and advantages. In this article, we will explore the key features, benefits, and applications of CHVDC contactors in the context of power distribution.

Understanding CHVDC Contactors

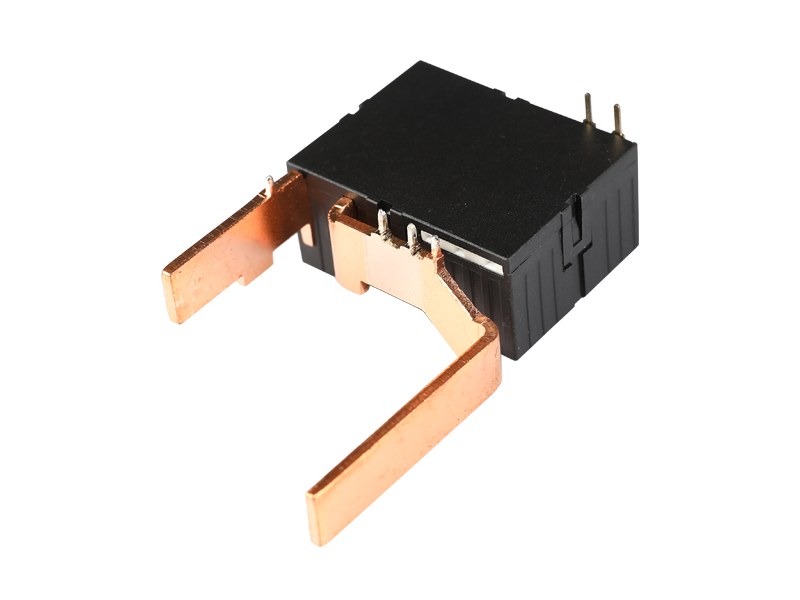

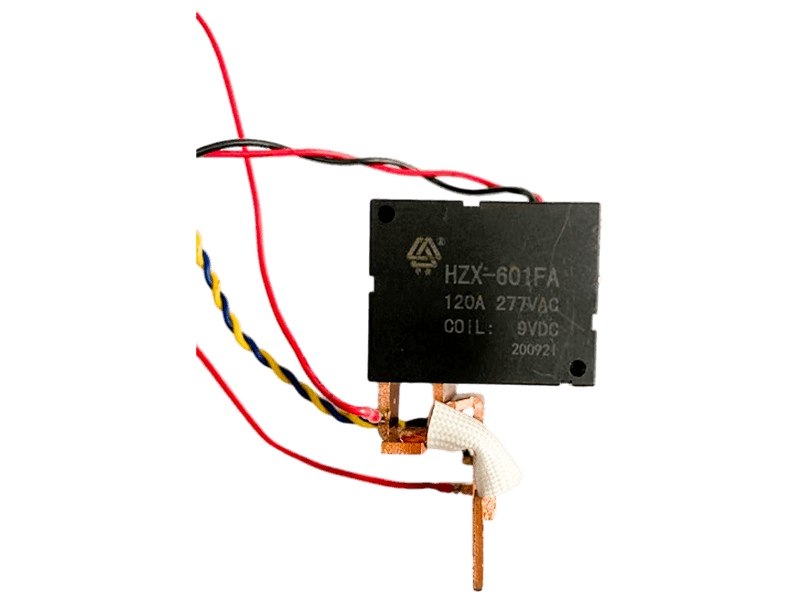

Ceramic high voltage direct current contactors are electromechanical devices designed to control the flow of electrical current in HVDC systems. Unlike traditional contactors that use metal components, CHVDC contactors employ ceramic materials due to their exceptional electrical and thermal properties. These materials offer improved insulation capabilities, high voltage ratings, and excellent resistance to arcing and wear, making them ideal for high-power applications.

Key Features and Advantages

Enhanced Electrical Insulation: Ceramic materials, such as alumina (Al2O3) or beryllium oxide (BeO), provide superior electrical insulation compared to traditional metal-based contactors. This characteristic allows CHVDC contactors to handle high voltages without the risk of electrical breakdown or leakage currents, ensuring reliable and safe operation.

High Voltage Ratings: CHVDC contactors can handle extremely high voltages, typically ranging from several kilovolts (kV) to several tens of kilovolts. This capability makes them suitable for HVDC applications, where voltages in the range of hundreds of kilovolts or even megavolts may be encountered.

Low Power Loss: The ceramic materials used in CHVDC contactors exhibit low electrical conductivity, reducing power losses and improving overall system efficiency. By minimizing energy dissipation, these contactors contribute to reduced transmission losses, resulting in cost savings and enhanced grid performance.

Arc and Wear Resistance: Ceramic materials possess excellent resistance to arcing and wear, enabling CHVDC contactors to maintain their performance over extended periods. This feature translates into longer operational lifetimes and lower maintenance requirements, enhancing the reliability of HVDC systems.

Applications of CHVDC Contactors

HVDC Power Transmission: CHVDC contactors play a critical role in HVDC power transmission systems, where they facilitate the control and switching of power flows between interconnected grids or renewable energy sources. Their high voltage ratings and efficient power handling capabilities make them well-suited for these demanding applications.

Renewable Energy Integration: With the increasing deployment of renewable energy sources, such as offshore wind farms and solar power plants, CHVDC contactors enable the integration of these variable energy sources into the grid. They ensure efficient power transfer from remote locations to load centers, contributing to the stability and reliability of renewable energy systems.

Electric Vehicle Charging Infrastructure: The rapid growth of electric vehicles (EVs) necessitates robust charging infrastructure. CHVDC contactors can be utilized in high-power charging stations, allowing efficient and reliable charging of EVs by converting AC power to DC power for battery charging.

Industrial Applications: CHVDC contactors find applications in various industrial sectors, such as steel production, mining, and manufacturing, where high voltage and high current operations are required. They enable precise control and reliable switching of electrical power, ensuring safe and efficient operation of industrial processes.

Ceramic high voltage direct current contactors offer a range of benefits and advancements in power distribution applications. Their unique electrical insulation properties, high voltage ratings, low power loss, and exceptional resistance to arcing and wear make them indispensable components