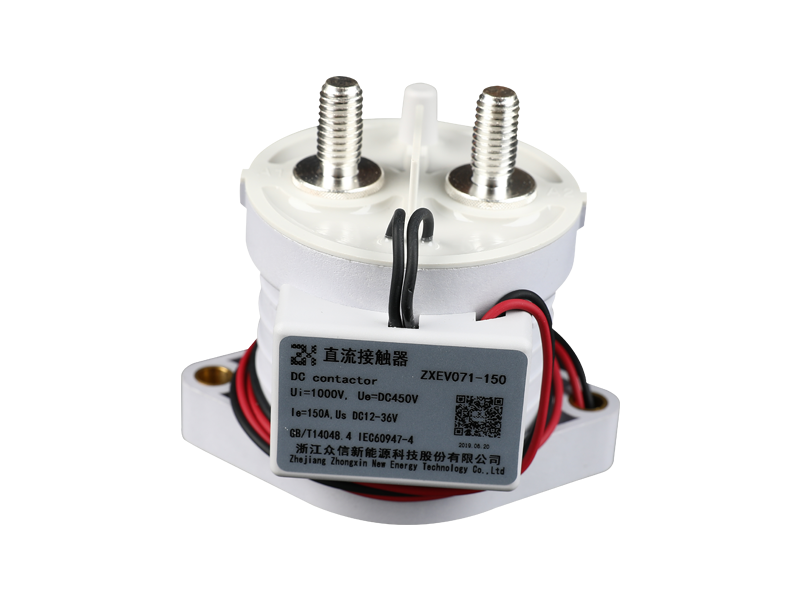

Epoxy-sealed medium-pressure DC contactors are typically used in various electrical applications, including Battery Management Systems (BMS) for certain scenarios. Here's some information on how they can be used in a BMS:

Protection and Isolation: In a BMS, one of the key functions is to protect the battery pack and the connected components from overcurrent, overvoltage, and other fault conditions. Medium-pressure DC contactors can be used to isolate sections of the battery pack or disconnect the battery from the rest of the system in case of a fault. The epoxy seal provides environmental protection and ensures that the contactors remain functional in various conditions.

Energy Management: BMSs are responsible for managing the energy flow within a battery pack, which includes charging, discharging, and balancing cells. DC contactors can play a role in controlling these processes by connecting or disconnecting different parts of the battery pack as needed for charging, discharging, or balancing.

Emergency Shutdown: In critical situations, such as thermal runaway or severe overvoltage, it may be necessary to quickly disconnect the battery pack from the system to prevent further damage or safety hazards. Medium-pressure DC contactors can provide this emergency shutdown capability.

Maintenance and Service: Contactors can be used to isolate sections of the battery pack during maintenance or service, ensuring the safety of technicians and preventing accidental short circuits.

Battery Pack Integration: These contactors can be integrated into the BMS control system, allowing for remote and automated control based on specific conditions and requirements.

Voltage and Current Ratings: When selecting DC contactors for use in a BMS, it's essential to consider the voltage and current ratings to ensure they meet the requirements of the specific battery system.

However, it's crucial to note that the choice of components in a BMS depends on various factors, including the size and type of battery pack, system voltage, safety requirements, and environmental conditions. Therefore, it's essential to consult the manufacturer's specifications and work with experienced electrical engineers to select the appropriate contactors and ensure they are integrated correctly into the BMS design to meet safety and performance goals.