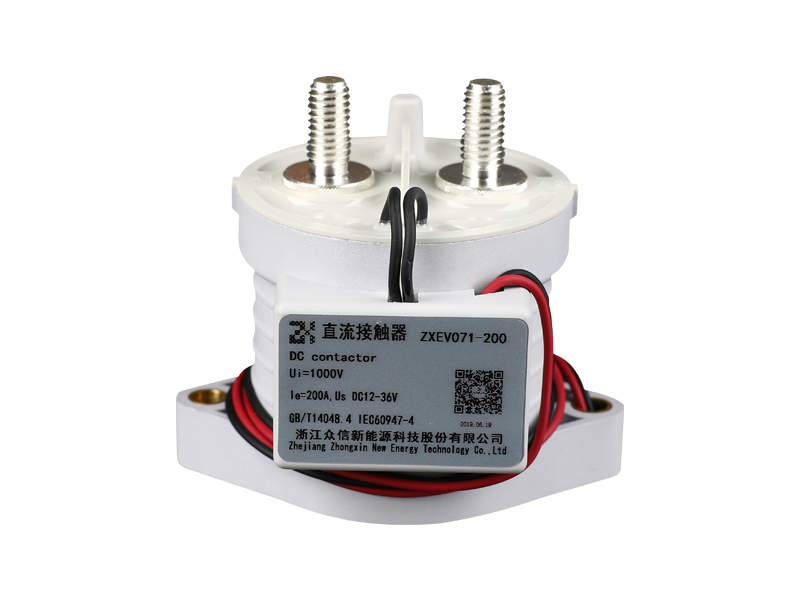

High Voltage Ratings: Epoxy High Pressure DC Contactors are designed to handle higher voltage ratings, making them suitable for high-power applications where traditional contactors might be limited.

Reduced Arcing: The use of high-pressure epoxy might help in reducing arcing (the formation of electric arcs) during switching operations. This can lead to enhanced safety and prolonged contactor lifespan.

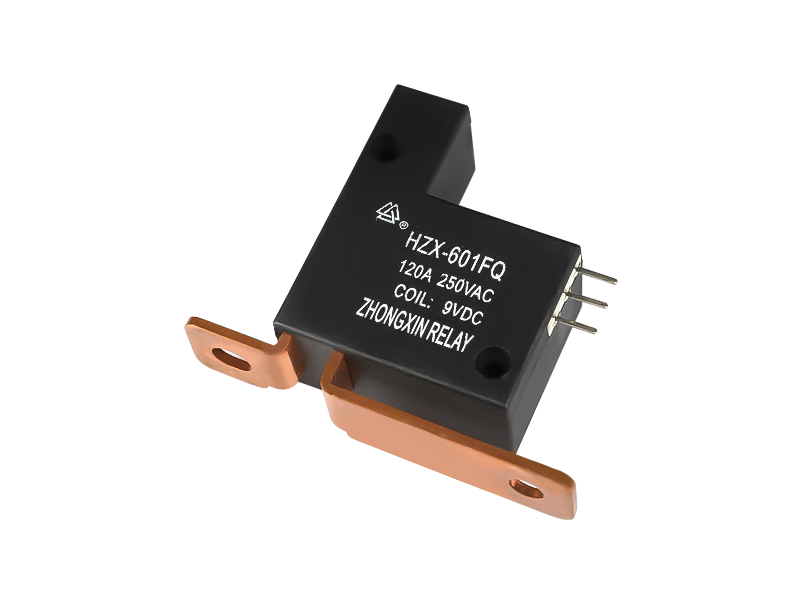

Compact Design: Epoxy-based contactors can be more compact and lightweight compared to traditional ones, allowing for space-saving in equipment design.

Improved Efficiency: Lower contact resistance in epoxy-based contactors can result in reduced energy losses and increased overall system efficiency.

Enhanced Environmental Protection: Epoxy resins can provide better protection against environmental factors such as moisture, dust, and chemicals, ensuring improved reliability in harsh conditions.

Lower Maintenance: The reduced arcing and wear in epoxy high-pressure contactors might lead to lower maintenance requirements and longer service life.

Faster Switching Speeds: In some cases, epoxy-based contactors might offer faster switching speeds, enabling more precise and dynamic control of power flow.

Please note that these advantages are general potential benefits that can be associated with advanced contactor designs like Epoxy High Pressure DC Contactors. Actual performance and advantages depend on the specific design, manufacturer, and the application in which they are used. Before using any specific type of contactor, it is essential to conduct a thorough analysis and consider the requirements of your particular application. Always consult with industry experts and manufacturers to make informed decisions regarding the selection of contactors for your projects.