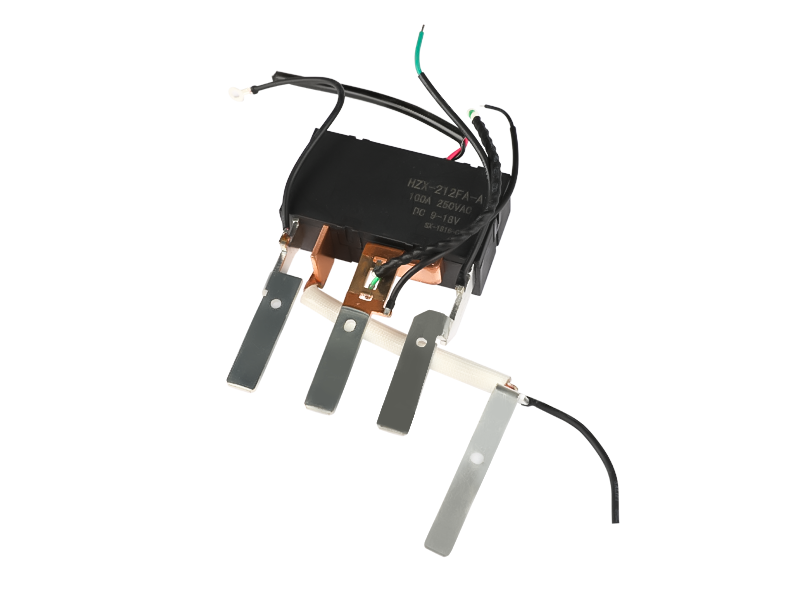

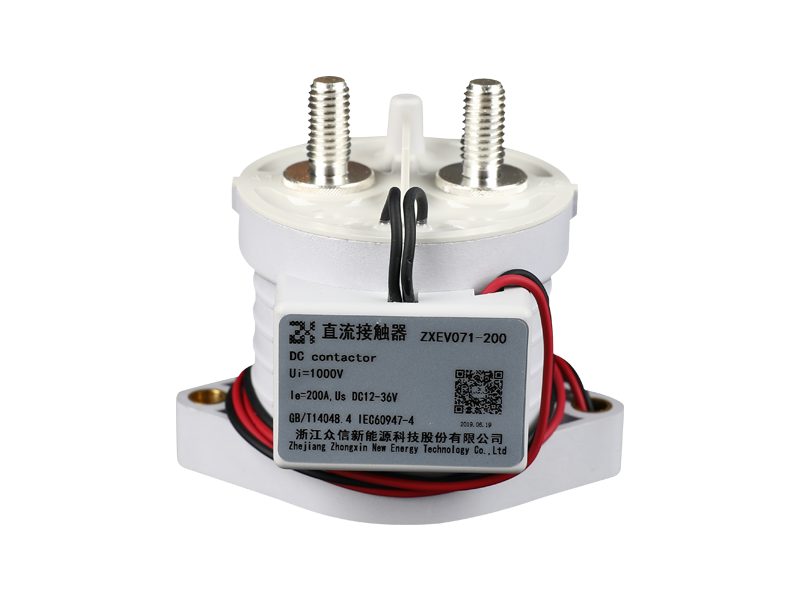

In high-voltage direct current transmission systems and related fields, the material selection of contactors is directly related to its operating performance and life. In these application scenarios, silver-nickel alloy has become one of the ideal materials for high-voltage DC contactors due to its excellent conductivity, wear resistance, excellent oxidation resistance and stability.

Silver-nickel alloy has excellent electrical conductivity and can ensure stable transmission of current under High Voltage Direct Current Contactors. This characteristic allows the silver-nickel alloy contact points to play a key role in the circuit, ensuring the smooth flow of current and reducing energy loss. At the same time, the conductive properties of silver-nickel alloy also ensure the stability of the contactor under high-frequency operation, allowing it to adapt to various complex electrical environments.

In addition to good electrical conductivity, silver-nickel alloys also offer excellent wear resistance. In high-voltage DC systems, contactors need to frequently connect and disconnect circuits, which places high demands on the wear resistance of the contact points. Silver-nickel alloy has excellent wear resistance and can maintain stable contact performance under long-term, high-load working conditions, effectively extending the service life of the contactor.

What's more worth mentioning is that silver-nickel alloy has excellent oxidation resistance and stability. In high-voltage DC systems, contact points are susceptible to oxidation and corrosion, resulting in reduced contact performance or even failure. The silver-nickel alloy has strong oxidation resistance and can maintain stable chemical properties in harsh working environments, effectively resisting oxidation and corrosion. This allows the silver-nickel alloy contact points to maintain stable contact performance over a long period of time, ensuring stable operation of high-voltage DC systems.

Silver-nickel alloy has become one of the ideal materials for high-voltage DC contactors due to its good conductivity, wear resistance, excellent oxidation resistance and stability. In high-voltage DC systems that require long-term stable operation, high-frequency operation, and harsh working environments, silver-nickel alloy contact points can exert their unique advantages and provide a strong guarantee for the stable operation of the system.