The rapid development of modern energy systems has brought increasing attention to devices that minimize power loss. Among them, the magnetic latching relay has emerged as a central component because of its low power consumption. Unlike conventional relays that require continuous current to maintain their state, this design allows the relay to retain its position without additional energy. This distinct operating principle is pushing the technology into the spotlight of global energy-saving initiatives.

A magnetic latching relay operates through a bistable mechanism. Once triggered by a short electrical pulse, it locks into either the “on” or “off” position without further energy input. This function not only reduces operational costs but also ensures stability in long-term applications. Compared with ordinary relays, the reduction in heat generation and energy waste highlights its technical advantage.

As memory relay switch technology gains adoption, its ability to retain state even during power interruptions is critical for smart meters, lighting control systems, and power distribution units. By minimizing standby losses, magnetic latching relays contribute directly to system efficiency and reliability. This efficiency is particularly vital in remote control circuits, where stable operation with minimal energy is required.

To illustrate the difference between magnetic latching relays and other relay types, the following table outlines their unique attributes:

| Feature | Magnetic Latching Relay | Conventional Electromagnetic Relay | Solid State Relay |

|---|---|---|---|

| Power Consumption | Minimal after switching | Continuous during operation | Low but constant |

| Coil Type | Single coil / dual coil options | Single coil only | N/A |

| Heat Generation | Very low | Higher due to constant current | Moderate |

| Memory Function | Yes (bistable) | No | No |

| Typical Applications | Smart meters, lighting, power grids | General switching devices | Industrial automation |

This structured comparison demonstrates why magnetic latching relay manufacturers emphasize energy-saving features when developing new models.

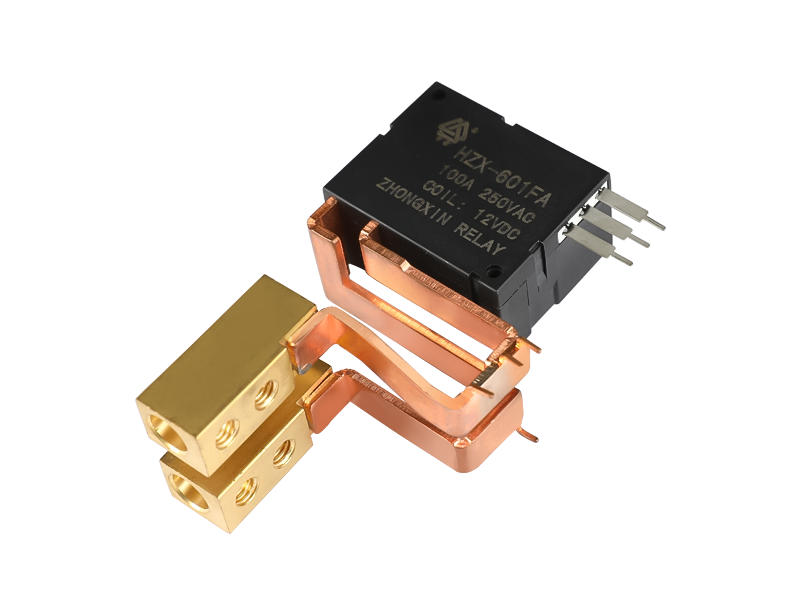

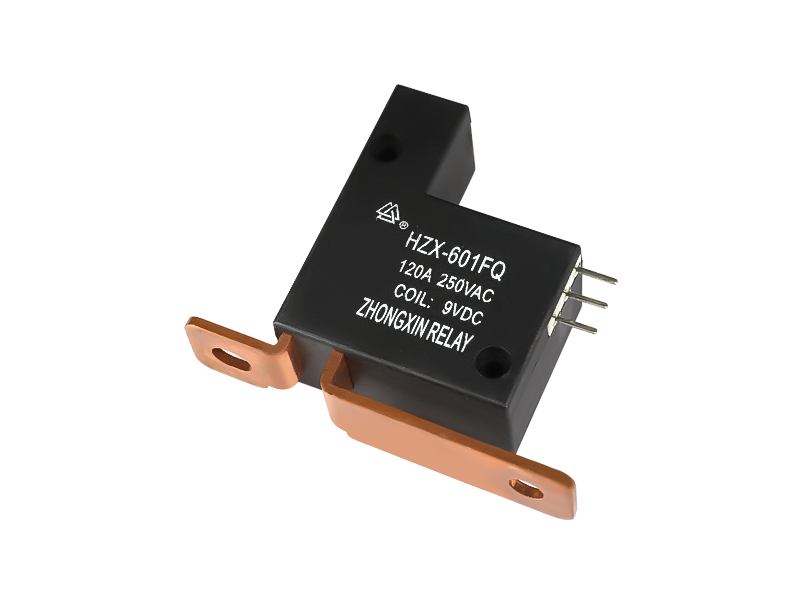

Within this category, there are variations such as single coil latching relay and dual coil latching relay. The single coil design is simpler, requiring a single pulse with reversed polarity to change states. Dual coil relays, on the other hand, offer greater control by dedicating separate coils for “on” and “off” operations. Both contribute to low power consumption relay applications, but manufacturers often differentiate based on cost, control precision, and integration needs.

Beyond the standard models, high current latching relays are tailored for energy distribution systems, while miniature latching relays serve compact automation devices. These variations ensure adaptability across different industries, reflecting the flexibility of this technology. PCB mount latching relay designs further expand their integration into advanced electronics, particularly where board space is limited.

The growing shift toward energy conservation ensures that magnetic latching relay manufacturers will continue to focus on refining coil technology, enhancing switching durability, and reducing operational footprints. As power distribution and automation systems evolve, the energy saving relay concept is becoming a standard rather than an option.

The defining feature of the magnetic latching relay—its low power consumption—is not just a technical advantage, but a response to global demands for efficiency and sustainability. With ongoing innovation in bistable relay structures, the industry is poised to reinforce its position as a cornerstone in smart systems.