Key Features of HVDC Contactors:

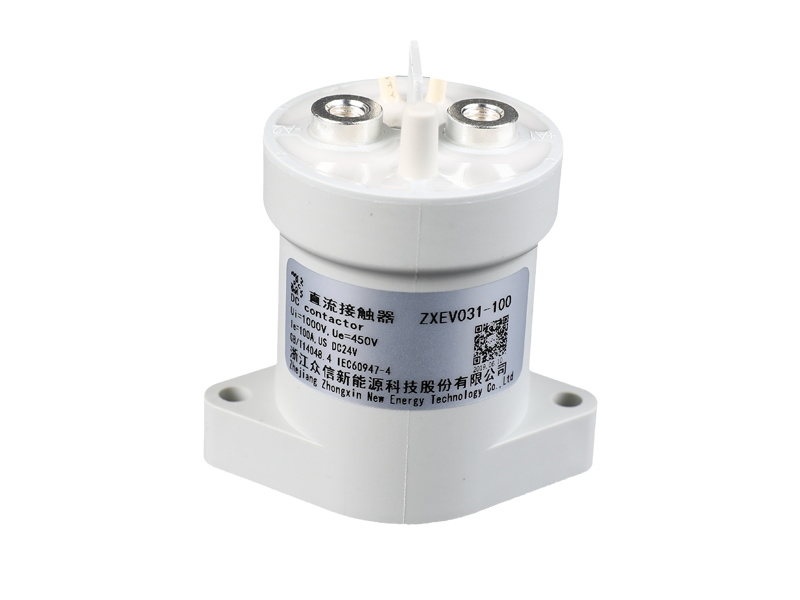

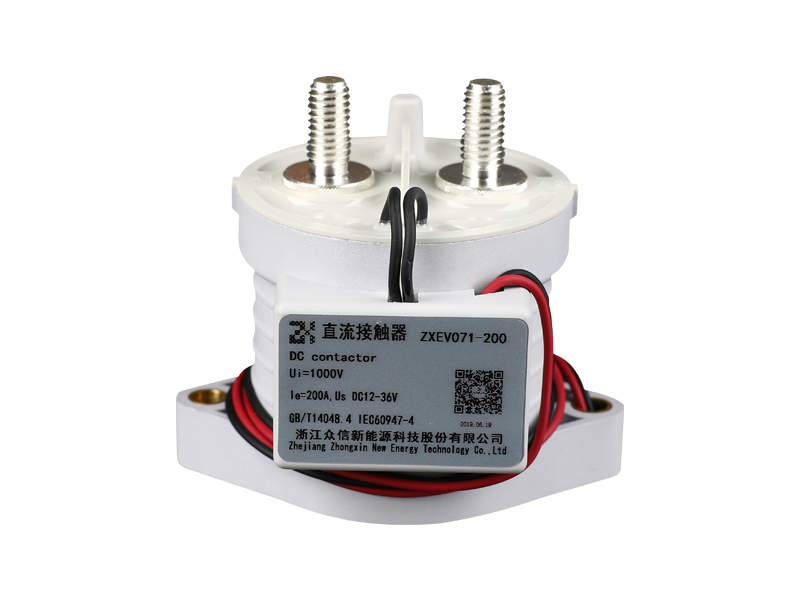

1. High Voltage Rating: HVDC contactors are engineered to withstand high voltage levels encountered in power transmission systems. They are designed to operate at voltage ratings typically ranging from several kilovolts up to several hundred kilovolts. The high voltage rating ensures that the contactors can handle the voltage levels present in HVDC circuits without compromising safety or performance.

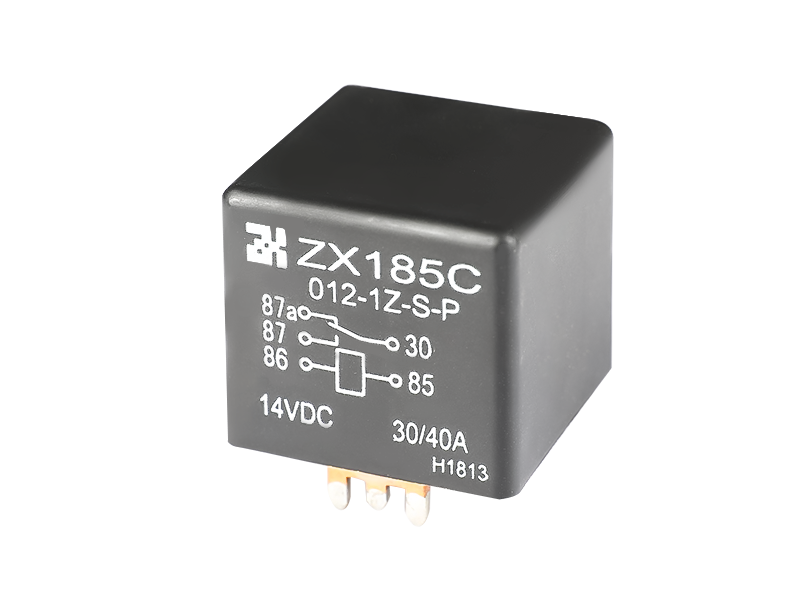

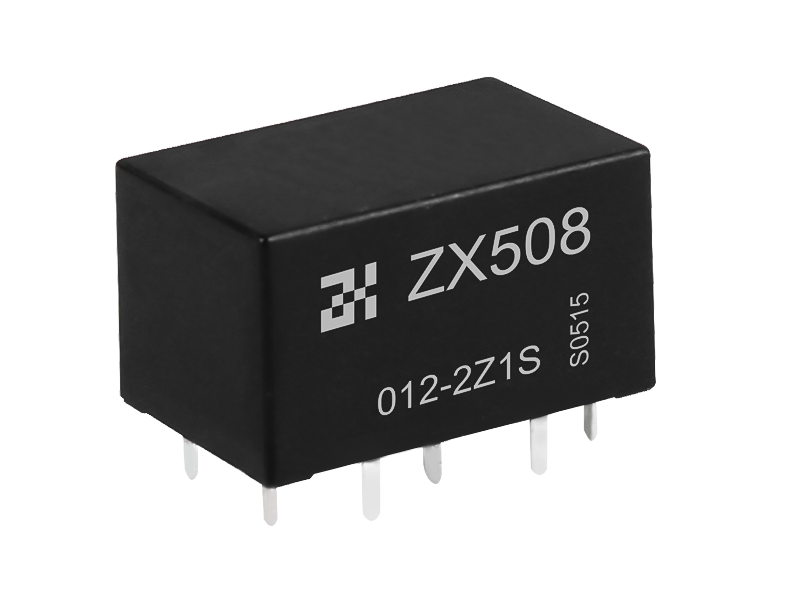

2. Direct Current Capability: Unlike traditional alternating current (AC) contactors, HVDC contactors are specifically designed to handle direct current (DC) applications. They are engineered to break and make DC circuits efficiently and reliably. The design considerations for HVDC contactors include factors such as arc interruption, current carrying capacity, and voltage polarity reversal to ensure optimal performance in DC environments.

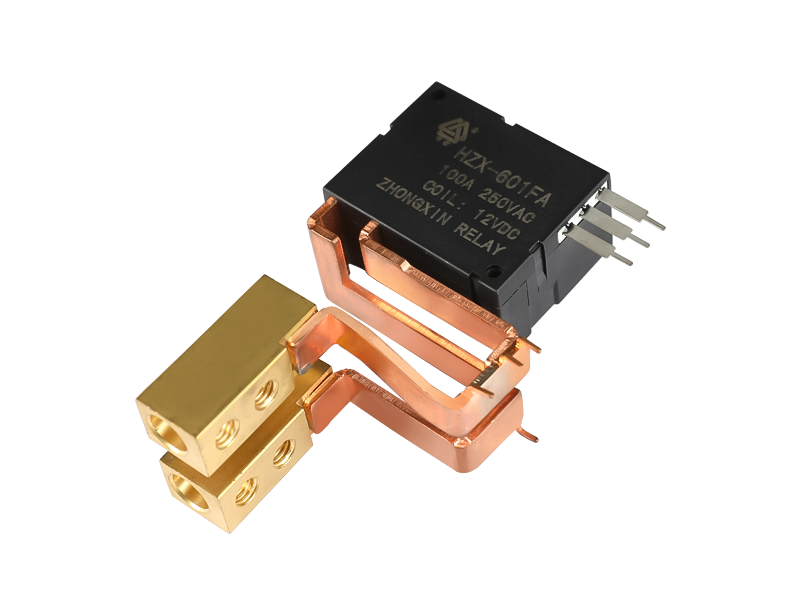

3. High Current Carrying Capacity: HVDC contactors are capable of carrying high current levels required for power transmission systems. These contactors are designed to handle currents ranging from hundreds of amperes to several kiloamperes. The high current carrying capacity allows for efficient transmission of large amounts of electrical power over long distances, minimizing power losses and maximizing transmission efficiency.

4. Fast Switching Speed: HVDC contactors are engineered for fast switching operations to facilitate the control and protection of HVDC systems. The contactors can transition between open and closed states quickly, allowing for rapid response in fault conditions or during system reconfiguration. The fast switching speed helps ensure the stability and reliability of HVDC transmission systems.

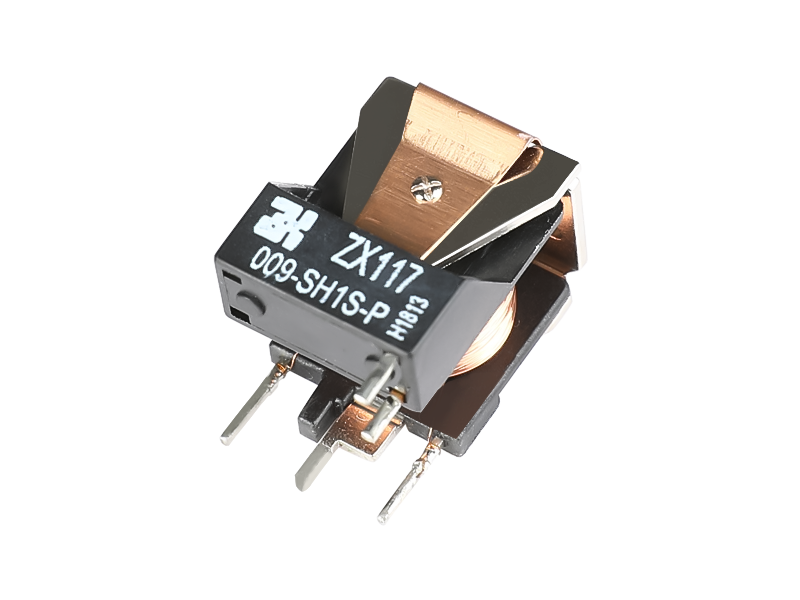

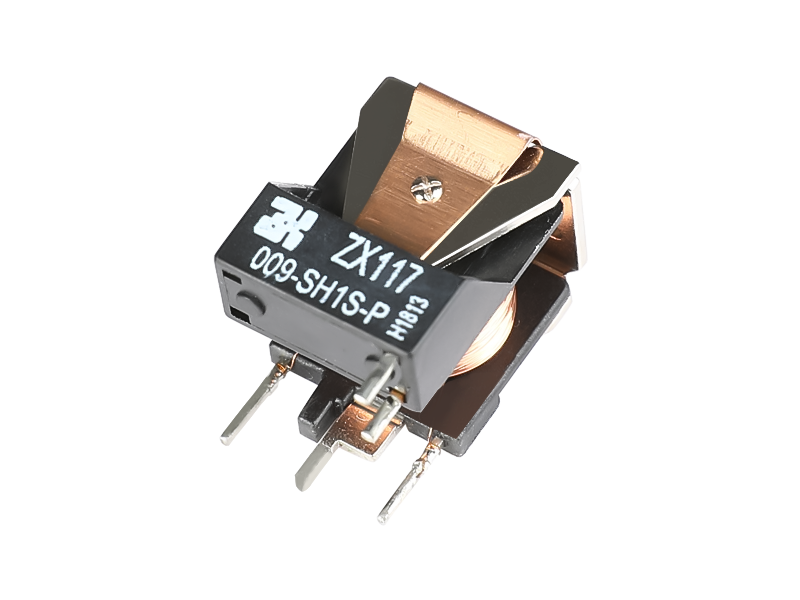

5. Robust Construction: HVDC contactors are built to withstand the demanding operating conditions encountered in power transmission systems. They are constructed using high-quality materials, such as specialized alloys and ceramics, to provide mechanical strength, resistance to high temperatures, and excellent electrical insulation properties. The robust construction ensures the durability and longevity of HVDC contactors in harsh environments.

Applications of HVDC Contactors:

1. HVDC Transmission Systems: HVDC contactors are extensively used in HVDC transmission systems to control the flow of electrical power between converter stations. These contactors play a crucial role in the operation, protection, and isolation of various sections of the HVDC transmission system, including converters, filters, reactors, and transmission lines. HVDC contactors enable efficient power transfer over long distances, making them vital components in interconnecting power grids and facilitating renewable energy integration.

2. Subsea Power Transmission: HVDC contactors find applications in subsea power transmission systems, where underwater cables are used to transmit electrical power over long distances. These contactors provide the necessary switching and control functions to regulate power flow and ensure reliable operation of subsea power transmission networks. HVDC contactors designed for subsea applications are engineered to withstand the challenges posed by the underwater environment, including high pressures and corrosive conditions.

3. Electric Vehicle Charging Infrastructure: HVDC contactors are utilized in high-power charging stations for electric vehicles (EVs). As EVs require increasingly higher charging power, HVDC contactors enable efficient and reliable charging of EV batteries at high voltages and currents. These contactors ensure safe and controlled power delivery to the vehicle, enabling faster charging times and supporting the widespread adoption of electric transportation.