Electromagnetic relays play a vital role in modern electrical systems by acting as switches that control circuits with low-power signals. These components are essential in various applications, from automotive systems to industrial equipment, ensuring that electrical devices perform effectively and efficiently. With such a variety of electromagnetic relays available, it’s crucial to understand how to select the suitable one for your needs.

What is an Electromagnetic Relay?

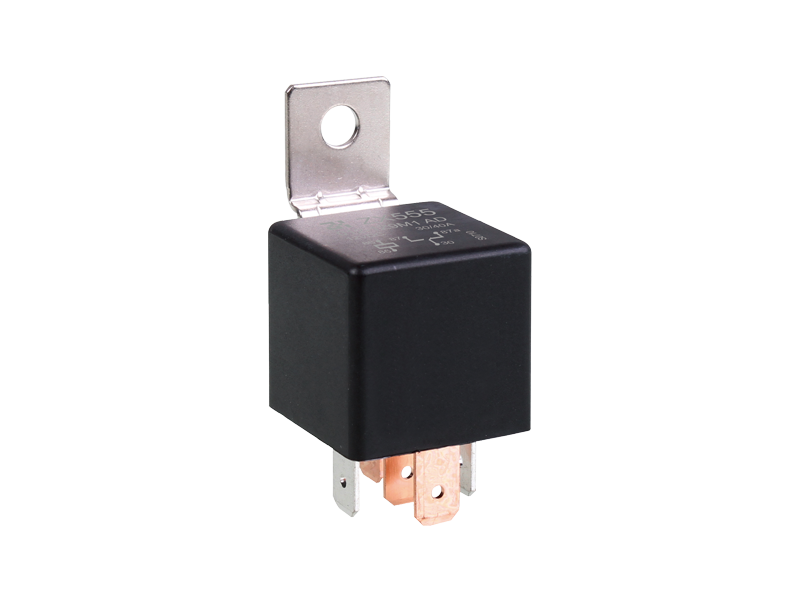

An electromagnetic relay is an electrically operated switch that uses an electromagnet to control the switching mechanism. When a current flows through the coil, it generates a magnetic field that pulls a lever or armature, closing or opening a set of contacts.

Key Components:

How Do Electromagnetic Relays Work?

When a small voltage is applied to the coil, it creates a magnetic field that moves the armature and activates the contacts, which either open or close depending on the relay’s configuration.

a. Load Requirements:

b. Switching Voltage and Current:

c. Contact Configuration:

d. Response Time:

e. Durability and Lifespan:

There are various types of electromagnetic relays, each suited for different applications. Let’s take a closer look:

| Relay Type | Application | Key Features |

|---|---|---|

| General Purpose Relay | Basic on/off control for appliances | Common in automotive, lighting, and HVAC systems. |

| Power Relay | Power switching for high-power circuits | Rated for higher current and voltage. |

| Timing Relay | Time delay control in automation systems | Provides time-based switching operations. |

| Thermal Relay | Overload protection in motors | Protects against overheating and overcurrent. |

| Solid-State Relay | Silent switching for sensitive devices | No mechanical parts, ideal for high-speed switching. |

a. Operating Temperature:

b. Vibration and Shock Resistance:

c. Protection from Dust and Moisture:

Coil Voltage:

Power Consumption:

Coil Voltage Range:

Contact Ratings:

When selecting an electromagnetic relay, always check for proper certifications and testing standards. Reputable relays will often come with certifications such as CE, UL, or IEC. These certifications ensure that the relay meets industry standards for safety and reliability.

While selecting a high-quality relay is critical, balancing cost against functionality is essential for project budgets. Relays come at various price points depending on their complexity, features, and application. Consider the overall project requirements and select the cost-effective solution that still ensures performance and durability.

Choosing the right electromagnetic relay for your system is a crucial decision that can impact the performance, reliability, and longevity of your electrical equipment. By understanding the key factors such as load requirements, contact configuration, environmental conditions, and coil voltage, you can make an informed choice that ensures efficient system operation.

1. What is the difference between normally open and normally closed contacts in a relay?

Normally open (NO) contacts are open when the relay is unenergized and close when energized. Normally closed (NC) contacts are closed when unenergized and open when energized.

2. How do I determine the coil voltage for my relay?

The coil voltage should match the control voltage of your circuit. For instance, if your control system operates at 12V DC, choose a 12V DC coil relay.

3. Can I use a relay for high-power applications?

Yes, as long as the relay is rated for the required voltage and current. For high-power applications, you should select a power relay designed to handle heavy loads.

4. What is the average lifespan of an electromagnetic relay?

The lifespan varies by type, but relays are rated for millions of operations. Thermal or high-frequency relays may have a shorter lifespan depending on usage.

5. Can I use an electromagnetic relay in environments?

Yes, but ensure you select a relay with appropriate environmental ratings, such as IP protection for moisture or dust resistance.