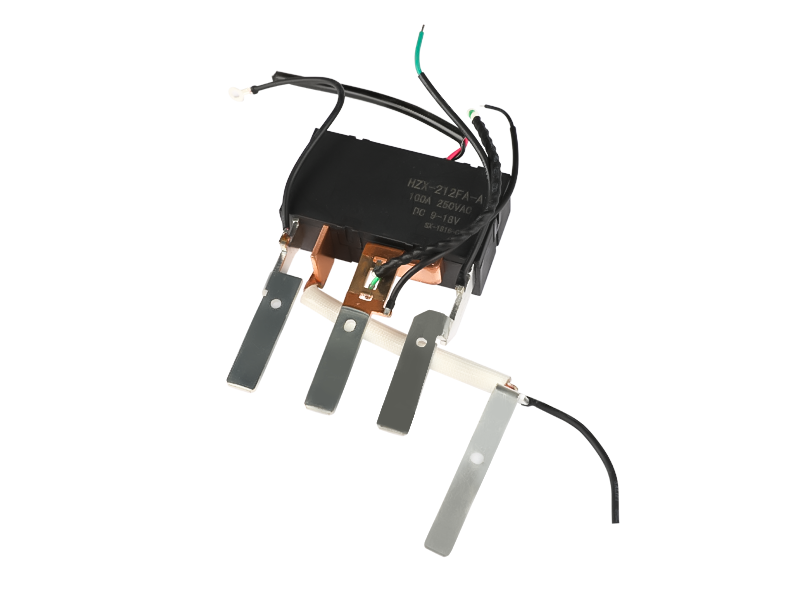

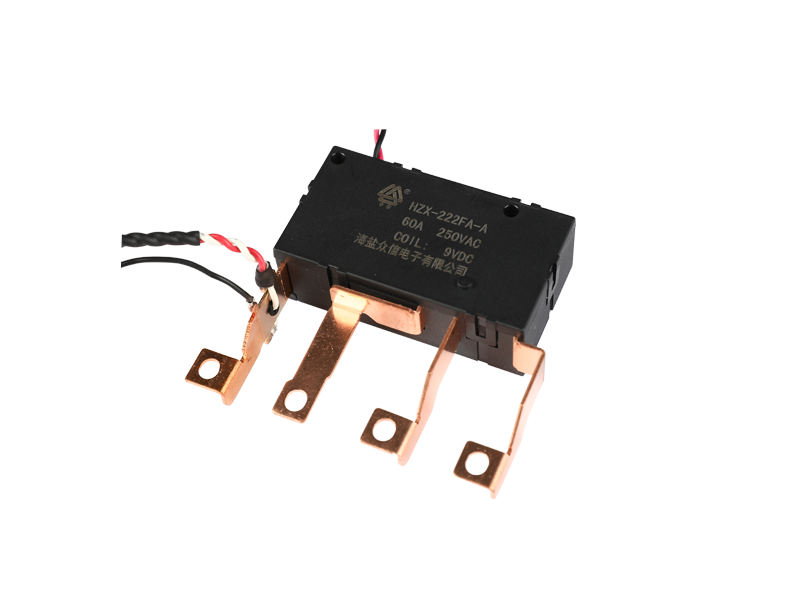

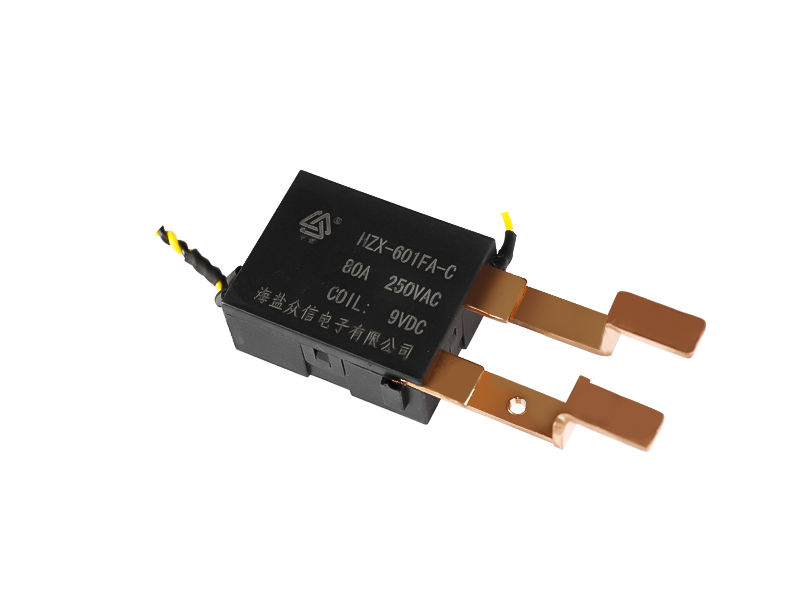

1. Small and lightweight:Internally adopt reliable sealing technology and filled with nitrogen which arc colling ability is high. It can cut off high voltage DC in a short time.

2. High contact reliability:Due to the contact sealed in the nitrogen, therefore it will be not oxidized, also achieving the contact of the dustproof and waterproof.

3. Safety and reliable:Use the professional explosion-proof structure design,to achieve a high degree of security,adopt magnetic quenching helps to cut-off the DC load quickly.

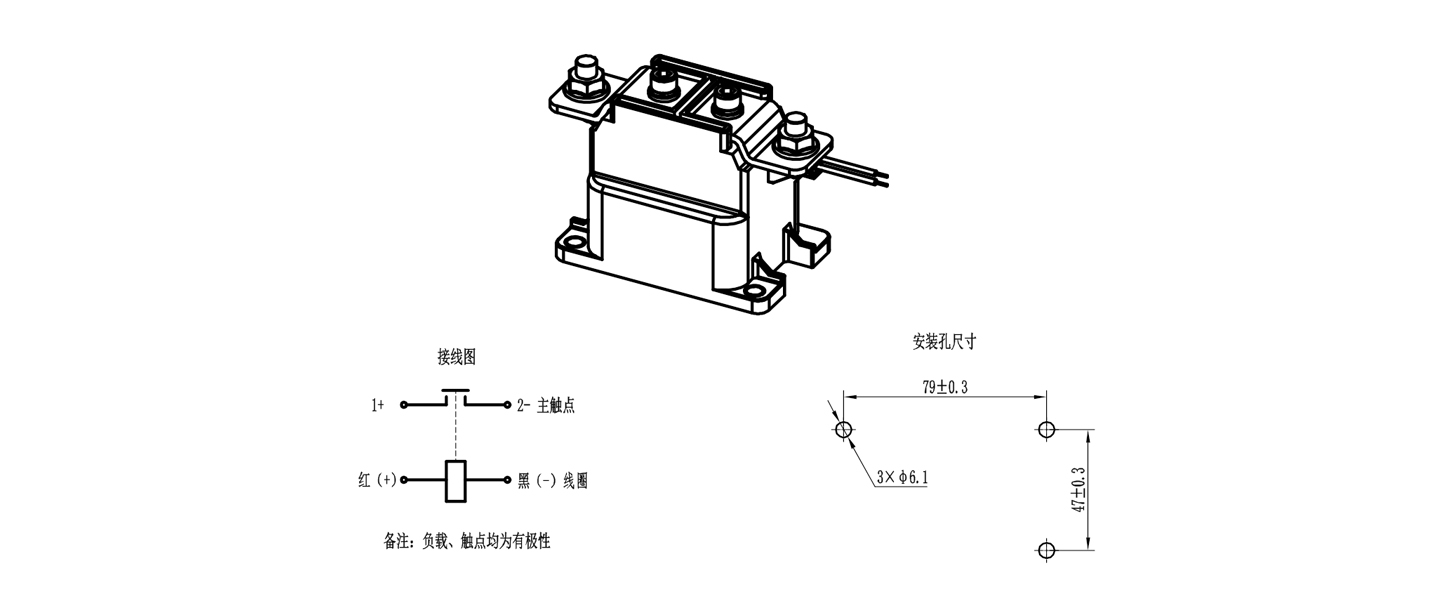

4. Application:DC charging pile, electric vehicles, hybrid vehicles, battery charging and discharging system,Photovoltaic power generation system such as dc high voltage application.

English

English